What is Surface Roughness?

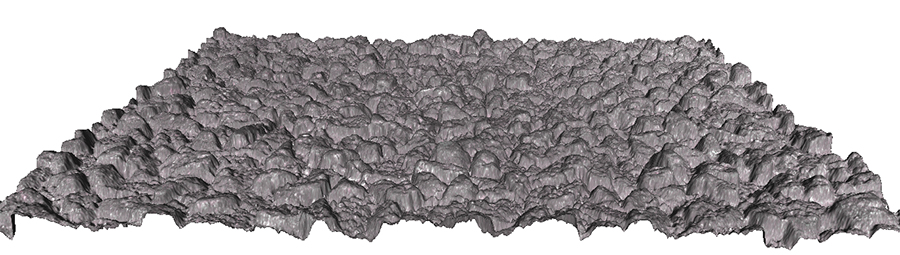

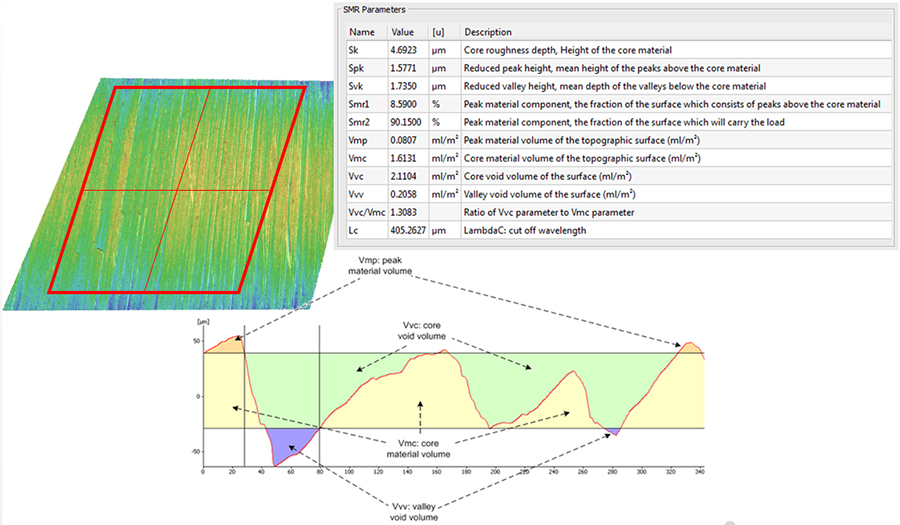

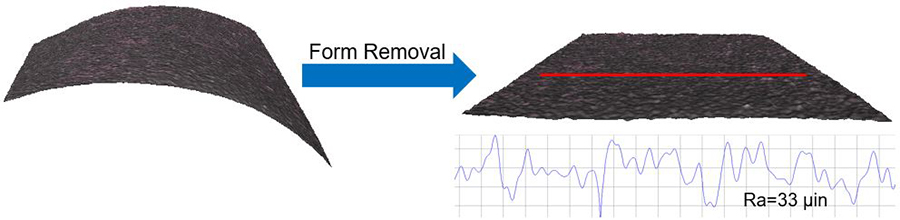

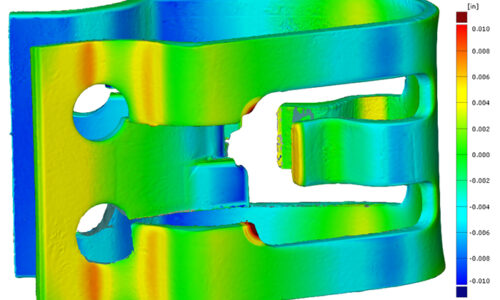

Surface roughness itself is defined as the frequency of peaks and valleys in the base material of a surface. In machined parts, such as those produced through our Wire EDM services, the surfaces are composed of complex shapes made of a series of peaks and valleys of widely varying heights, depths, and spacing. The surface roughness is affected by the asperities of that surface. Surface texture measurement is a critical, yet often overlooked, aspect of any manufacturing project.

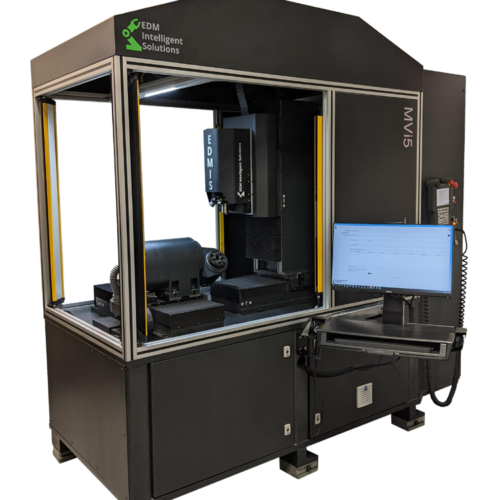

Surface Measurement Systems & Equipment

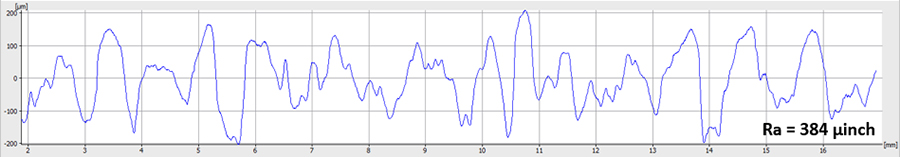

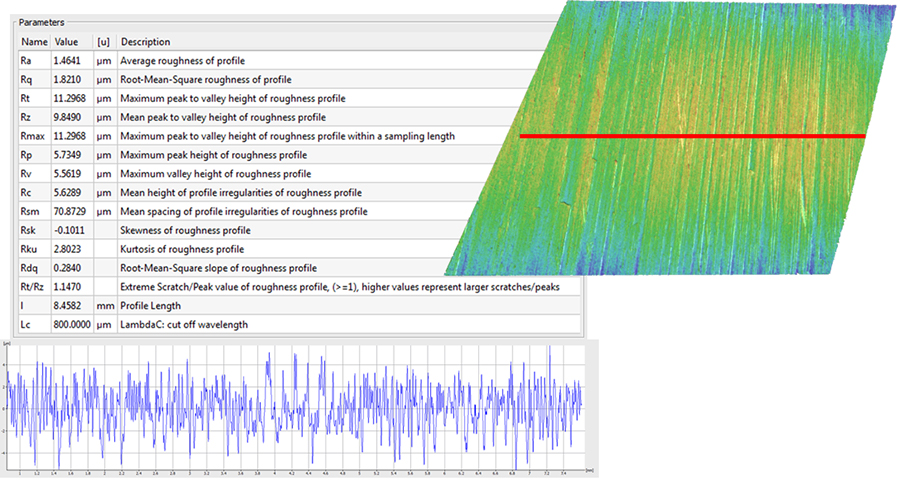

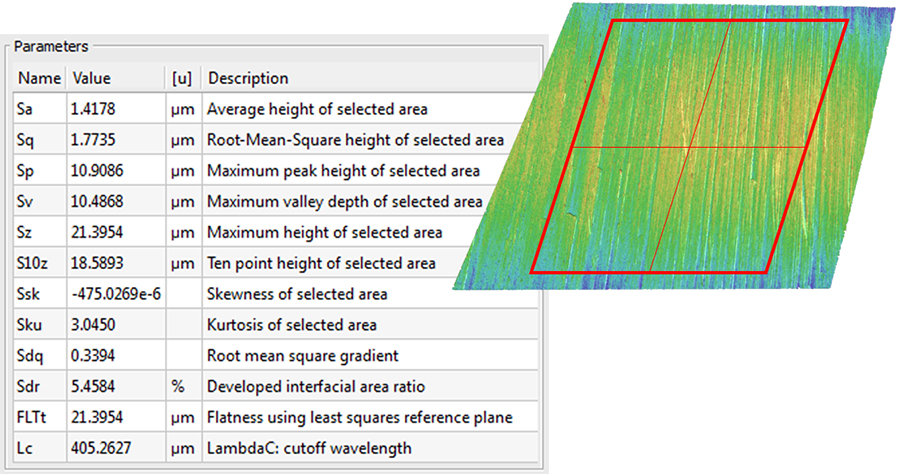

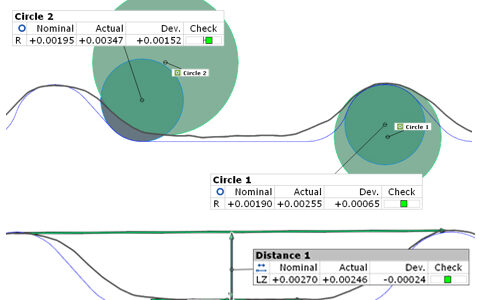

Surface Roughness Measurement both characterizes and quantifies a surface, which is crucial for precision applications like Sinker EDM components that require specific surface properties. Surface finish callouts are typically listed as requirements on engineering drawings along with the other dimensions and tolerances of a part. These surface roughness measurement values are calculated using a surface roughness tester, called a 3D surface profilometer, and are expressed as a single numeric parameter, Ra, if the calculation involves calculating the roughness of a part’s linear profile or Sa if it involves the roughness of a parts full surface area.