Aerospace Defect Detection on Spline Surfaces Using High-Resolution 3D Scanning

Executive Summary

Precision aerospace components require strict dimensional integrity and surface quality to meet performance and safety standards. At EDM Intelligent Solutions, we deliver high-resolution 3D metrology services capable of micron-level accuracy to support the inspection, validation, and defect detection needs of aerospace manufacturers. This report highlights our non-contact 3D scanning process applied to a precision aerospace gear, demonstrating our advanced defect detection capability on spline surfaces.

Overview of 3D Metrology Capabilities

EDM Intelligent Solutions offers advanced 3D metrology services leveraging state-of-the-art scanning systems that produce high-density point clouds for micron-scale resolution. Our system captures complex geometries, identifies surface anomalies, and provides precise form measurements critical for aerospace applications.

Key capabilities include:

- Non-contact 3D scanning of complex geometries

- Micron-level form measurements including radii, angles, slot widths, and step heights

- In-depth surface defect detection including FOD (foreign object debris), cracks, pits, and more

- Data visualization and reporting for GD&T compliance and manufacturing feedback

Application Case Study: Defect Detection on Spline Surface

Component Overview

- Type: Precision Aerospace Gear

- Material: Hardened Stainless Steel

- Inspection Challenge: Detect microscopic surface defects on spline geometry in a non-contact manner

Technology Used

- System: MVi5 3D Metrology Center

- Process: Three-step high-resolution 3D scanning and analysis workflow

Three-Step Inspection Process

Step 1: Full 3D Surface Scan

The aerospace gear is scanned using the MVi5 3D Metrology Center to produce a complete high-resolution digital model of the component. This model includes spline features and internal/external geometries with detail down to the micron scale.

Step 2: Form Measurement & Analysis

Using profile slicing techniques across spline features, we extract dimensional data such as:

- Tooth-to-tooth symmetry

- Radius deviations

- Step heights and edge break consistency

- Slot widths and angular misalignments

This allows for comparison against engineering specifications and CAD data.

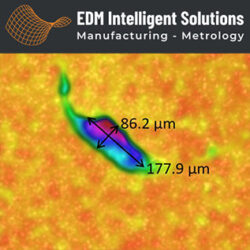

Step 3: Defect Detection & FOD Identification

Through high-density surface scanning and data filtering, localized surface irregularities are identified. In this case:

- Minor pits and nicks on the spline surface were detected

- FOD residues were visually and dimensionally confirmed

- All anomalies were mapped and quantified for corrective action

Results & Value Delivered

- Non-destructive analysis of high-value aerospace components

- Detection of critical surface defects that would be missed by traditional inspection

- Improved process feedback for manufacturers regarding tooling wear, handling damage, and environmental contamination

- Digital recordkeeping of inspection reports and 3D models for traceability

Conclusion

High-resolution 3D metrology is redefining quality assurance in the aerospace industry. At EDM Intelligent Solutions, our advanced non-contact scanning technologies—paired with expert-level form measurement and defect detection—ensure that your most complex components meet stringent specifications every time.

About EDM Intelligent Solutions

EDM Intelligent Solutions is a precision manufacturing and metrology service provider specializing in electrical discharge machining, advanced 3D inspection, and process automation. With deep experience in aerospace and defense sectors, we deliver mission-critical component validation to the highest standards.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.