Aerospace Turbine Blade Inspection Using Advanced 3D Scanning Technology

Executive Summary

The demand for complex turbine blades has intensified with advancements in aero-engine and land-based gas turbine performance. These components require precise dimensional integrity, including intricate airfoil shapes, root geometries, and shaped cooling holes with tighter tolerances. EDM Intelligent Solutions delivers fully automated, non-contact 3D metrology services that ensure the accuracy, conformity, and performance of these high-value components. This report demonstrates our turbine blade inspection capabilities using our MVi5 3D Metrology Center.

Overview of 3D Metrology Capabilities

EDM Intelligent Solutions applies state-of-the-art 3D scanning systems for non-contact measurement and defect detection on turbine blades. Our advanced systems deliver micron-level inspection across multiple geometric features and surface conditions in a fully automated fashion.

Key inspection capabilities include:

- Cooling hole inspection (location, diameter, shape, breakthrough, back-strike)

- Blade root geometry and fitment analysis

- Airfoil shape conformity to CAD models

- Surface roughness measurement on blade edges

- Full 3D point cloud generation for digital records and traceability

Application Case Study: Turbine Blade Inspection

Component Overview

- Type: Turbine Blade

- Industry Use: Aerospace and Power Generation

- Metrology System: MVi5 3D Metrology Center

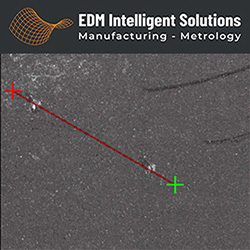

Cooling Hole Inspection Process

The turbine blade inspection was performed using the MVi5 3D Metrology Center in a fully automated routine. Both straight and shaped cooling holes were scanned using high-resolution, non-contact sensors. Key parameters measured included:

- Hole presence and count verification

- Hole location relative to datum features

- Shape conformity for shaped and diffused holes

- Surface roughness within and around the hole

- Breakthrough and back wall penetration (back-strike)

All inspection data was stored as either statistical summaries or full 3D point cloud datasets for each cooling hole. This level of traceability allows for comprehensive part verification, quality reporting, and process feedback.

Results & Value Delivered

- Automated, repeatable inspection of complex blade geometries

- Enhanced visibility into cooling hole integrity and surface condition

- Comprehensive defect detection and tolerance analysis

- Improved traceability through digital inspection records

Conclusion

Precision metrology is critical in maintaining the performance and reliability of turbine blades in aerospace and power generation systems. EDM Intelligent Solutions offers cutting-edge, non-contact 3D inspection capabilities that address the challenges of inspecting modern turbine blade features, providing our customers with unmatched quality assurance and engineering insight.

About EDM Intelligent Solutions

EDM Intelligent Solutions is a premier provider of electrical discharge machining and advanced 3D metrology services. Serving the aerospace, medical, and energy sectors, we specialize in automated inspection, precision measurement, and surface analysis for the most demanding components and assemblies.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.