Automotive Casting Defect Detection Using High-Resolution 3D Form Measurement

Executive Summary

Casting defects in engine components can lead to performance degradation, safety issues, and increased production costs. Accurate and non-destructive detection of such defects is essential in modern automotive manufacturing. At EDM Intelligent Solutions, we utilize advanced 3D scanning technologies to perform high-resolution form measurement and defect detection down to the micron scale. This report demonstrates our casting inspection capabilities using our MVi5 3D Metrology Center on an aluminum engine casting.

Overview of 3D Metrology Capabilities

Our 3D metrology services leverage high-density scanning and advanced profile analysis to inspect complex part geometries. By slicing through 3D scan data, we can accurately extract and evaluate dimensional features such as radii, angles, slot widths, height steps, and more—all without physically contacting or damaging the part.

Key capabilities include:

- µm-scale 3D scanning and form measurement

- Detection of casting flaws, voids, and surface discontinuities

- Non-contact inspection suitable for soft or complex surfaces

- Traceable dimensional reporting and digital recordkeeping

Application Case Study: Engine Casting Defect Detection

Component Overview

- Type: Engine Casting

- Material: Aluminum

- Metrology System: MVi5 3D Metrology Center

- Metrology Service: Form Measurement and Defect Detection

Casting Defect Detection Process

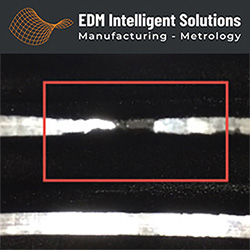

The engine casting was scanned using the MVi5 3D Metrology Center to generate a full, high-resolution 3D point cloud. This data was then sliced into multiple cross-sectional profiles, allowing our team to evaluate key form dimensions and identify inconsistencies or irregularities in geometry that indicate potential defects.

Dimensional attributes such as slot widths, radii, and height steps were automatically measured and compared against nominal design values. Deviations were flagged and analyzed to determine if they originated from shrinkage, porosity, or tooling issues. This process provided a detailed assessment of component conformance without requiring destructive testing.

Results & Value Delivered

- Non-contact, micron-scale inspection of aluminum casting geometry

- Early detection of defects and deviations from nominal form

- Reduced scrap rates and improved first-pass yield

- Traceable digital records for quality documentation and process improvement

Conclusion

Casting defect detection using advanced 3D form measurement provides automotive manufacturers with a fast, accurate, and non-destructive method to ensure component integrity. EDM Intelligent Solutions offers the technology and expertise required to meet the high standards of modern engine manufacturing, delivering results that support quality, safety, and operational efficiency.

About EDM Intelligent Solutions

EDM Intelligent Solutions provides advanced manufacturing and metrology services to the automotive, aerospace, and medical industries. With expertise in 3D inspection and electrical discharge machining, we help our customers ensure product quality, performance, and compliance.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.