Consumer Products Aluminum Can Form Inspection & CAD Comparison

Executive Summary

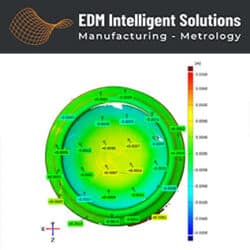

Precision packaging components, such as aluminum beverage cans, require tight tolerance inspection to ensure structural integrity, tooling validation, and design compliance. EDM Intelligent Solutions provides advanced 3D metrology services for consumer products using high-resolution, non-contact scanning. This report outlines the form inspection process used to analyze an aluminum can’s critical features and compare them to the original CAD model.

Overview of 3D Metrology Capabilities

Using robotic 3D scanning and data processing systems, EDM Intelligent Solutions can inspect parts of virtually any shape, size, or material. Our equipment captures high-resolution form and surface data to perform full dimensional inspections, difference measurements, and CAD comparisons—all from a single scan.

Key capabilities include:

- Form measurement of consumer and packaging components

- Comparison to CAD for design conformance validation

- Profile extraction and dimensional analysis

- Robotic automation for consistent, repeatable inspection

Application Case Study: Aluminum Beverage Can Inspection

Component Overview

- Type: Beverage Can and Tooling

- Material: Aluminum

- Metrology System: RSH-M10 Robotic 3D Metrology System

- Metrology Services: Form Measurement and Difference Measurement

Inspection Process

The inspection process began with scanning the aluminum can using the RSH-M10 Robotic 3D Metrology System. The scan produced a full 3D dataset that captured intricate surface details and geometry, including critical internal features.

Key features inspected included the inner nose radius and stand diameter. Profile extractions from the scan were used to calculate geometric dimensions and compare actual measurements to CAD references. This process helps ensure tooling accuracy and packaging compliance with design specifications.

Results & Value Delivered

- Non-contact inspection of thin-walled aluminum packaging

- Fast, automated measurement of critical internal and external features

- CAD comparison enables tooling validation and process feedback

- Improved quality control in consumer packaging production

Conclusion

Form inspection and CAD comparison are essential tools in the manufacturing of high-volume consumer packaging products such as aluminum cans. EDM Intelligent Solutions’ advanced 3D metrology systems provide fast, accurate, and repeatable inspection results that support product design, tooling validation, and quality assurance.

About EDM Intelligent Solutions

EDM Intelligent Solutions delivers precision manufacturing and metrology services across a range of industries including aerospace, medical, scientific, and consumer products. With robotic automation and non-contact scanning technology, we provide world-class dimensional inspection solutions for today’s most demanding applications.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.