- About EDMIS

- Applications Gallery

- Industries Served

- Aerospace & Defense Manufacturing and 3D Metrology Solutions

- Automotive Component Manufacturing & 3D Metrology Solutions

- Electronics Manufacturing & 3D Metrology Solutions

- Energy Component Manufacturing & 3D Metrology Solutions

- Custom Interconnect Solutions & Mil-Spec Connectors

- Precision Medical Metrology Services & Pharmaceutical Manufacturing

- Scientific Component Manufacturing & 3D Metrology Solutions

- Latest News

- Contact Us

- Request A Quote

- Nationwide Service Areas

Consumer Products Beauty Tool Abrasive Roughness Measurement on Spherical Surfaces

Executive Summary

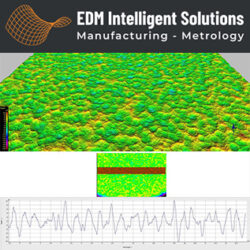

In the competitive consumer beauty market, the performance of abrasive tools relies heavily on consistent and controlled surface roughness. At EDM Intelligent Solutions, we provide advanced, non-contact 3D metrology services that deliver precise roughness measurements—even on complex geometries such as spherical and contoured surfaces. This report details our inspection methodology for a beauty tool with abrasive characteristics using our MVi5 3D Metrology Center.Overview of 3D Metrology Capabilities

Surface roughness measurement involves quantifying the microscopic peaks and valleys on a material’s surface. EDM Intelligent Solutions uses high-resolution 3D scanning systems to analyze surface texture down to the micron scale. Our Form Removal process enables roughness data extraction from surfaces with inherent curvature, such as spheres, threads, and radii. Key capabilities include:- Non-contact surface roughness measurement down to µm scale

- Form removal for accurate texture analysis on complex surfaces

- Applicable to spherical, threaded, and freeform geometries

- Ra measurement with tolerances as tight as ±0.005 mm

Application Case Study: Abrasive Beauty Tool Inspection

Component Overview

- Type: Abrasive Beauty Tool

- Material: Aluminum

- Metrology System: MVi5 3D Metrology Center

- Metrology Services: Form Removal and Surface Roughness Measurement

- Target Tolerance: ±0.005 mm Ra

Inspection Process

The abrasive beauty tool with a spherical aluminum surface was scanned using the MVi5 3D Metrology Center. The resulting high-resolution dataset was analyzed using a form removal algorithm to isolate the true roughness characteristics from the underlying spherical geometry. Surface profiles were extracted across targeted areas to calculate Ra and other roughness parameters. The results were evaluated against the design tolerance of ±0.005 mm to ensure product performance and consistency in manufacturing.Results & Value Delivered

- Accurate, non-destructive roughness analysis on curved surfaces

- Clear identification of abrasive texture within defined tolerances

- Enhanced quality control for consumer-facing components

- Data-driven validation for tooling and surface treatments

Conclusion

Surface roughness plays a vital role in the performance of beauty tools. EDM Intelligent Solutions delivers precise, repeatable, and non-contact surface texture measurements—even on complex geometries—through our advanced 3D metrology systems. Our methodology ensures that cosmetic and personal care products meet both aesthetic and functional standards.About EDM Intelligent Solutions

EDM Intelligent Solutions provides precision machining and metrology services to a broad spectrum of industries including aerospace, medical, consumer goods, and scientific research. Our metrology team integrates cutting-edge inspection systems with intelligent workflows to support quality assurance, product development, and advanced manufacturing.Downloadable PDF of Applications Report