Energy Sector Accelerator Structure Component Measurement and CAD Comparison

Executive Summary

Precision components used in particle accelerators must meet extremely tight dimensional tolerances and surface specifications to function reliably under high-energy conditions. EDM Intelligent Solutions offers advanced 3D metrology services to support these demands. This report highlights our form and CAD comparison inspection process applied to niobium-based accelerator structure components.

Overview of 3D Metrology Capabilities

Using high-resolution 3D scanning systems, we extract cross-sectional profiles and conduct difference measurements by overlaying 3D scan data with engineering CAD models. This allows for rapid visualization and quantification of any deviations in geometry, helping ensure product conformance and optimize manufacturing processes.

Key capabilities include:

- Micron-level optical 3D scanning and mesh generation

- Profile slicing for dimensional measurements (radii, angles, steps, slots)

- Difference measurement with CAD overlay for deviation mapping

- Quantitative deviation reporting for manufacturing feedback

Application Case Study: Particle Accelerator Structure Component

Component Overview

- Type: Accelerator Structure Component

- Material: Niobium

- Metrology System: MVi5 3D Metrology Center

- Metrology Services: Form Measurement, Average Deviation from CAD

Inspection Process

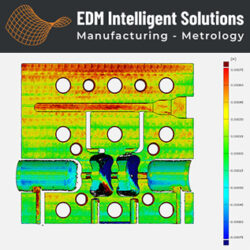

The niobium component was scanned using our MVi5 3D Metrology Center. A full surface mesh was generated and compared to the nominal CAD model to detect any deviation in form or geometry. Profiles were sliced through critical areas to measure features such as radii, slot widths, height steps, and angles.

CAD overlay difference measurement was then performed, revealing form variations across the entire structure. Average deviation values were reported and visualized to guide engineering decisions.

Results & Value Delivered

- Non-contact inspection of complex accelerator geometry

- CAD-based deviation analysis to ensure dimensional compliance

- Enhanced insight into part form using profile slicing and overlay tools

- Precision documentation for QA and production optimization

Conclusion

Particle accelerator components made from advanced materials like niobium demand exceptional accuracy and traceability. EDM Intelligent Solutions’ 3D metrology systems provide a complete, non-contact solution for dimensional inspection and CAD validation. This ensures conformance with design intent and supports the continued innovation in high-energy research environments.

About EDM Intelligent Solutions

EDM Intelligent Solutions is a leader in precision metrology and manufacturing for high-tech industries including energy, aerospace, defense, and scientific research. We specialize in high-resolution 3D scanning, CAD comparison, and advanced data analysis to help manufacturers improve quality, reduce costs, and accelerate development.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.