Energy Sector Proppant Embedment Inspection

Executive Summary

The behavior of proppants during hydraulic fracturing is critical to the effectiveness and efficiency of oil extraction. EDM Intelligent Solutions offers precise 3D Metrology Services designed to inspect and quantify proppant embedment behavior using non-contact, high-resolution scanning. This report outlines our approach to proppant embedment analysis using advanced surface texture and bearing area curve measurements, performed with the MVi5 3D Metrology Center.

Overview of 3D Metrology Capabilities

Our team uses state-of-the-art 3D scanning technology to generate detailed surface maps that provide insight into microscopic features and embedment patterns. These measurements are essential in analyzing the interactions between proppants and formation materials such as shale during hydraulic fracturing operations.

Key capabilities include:

- High-resolution, non-contact surface scanning

- Surface texture analysis for proppant impact zones

- Bearing area curve generation to assess load-bearing characteristics

- Quantitative metrics for research, development, and quality control

Application Case Study: Proppant Embedment Analysis

Component Overview

- Type: Proppant Embedment Sample

- Material: Shale

- Metrology System: MVi5 3D Metrology Center

- Metrology Services: Surface Area Texture, Bearing Area Curve

Inspection Process

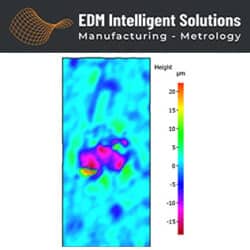

A 3D surface scan was performed on shale samples containing embedded proppants using the MVi5 system. The resulting data was processed to extract localized surface texture and bearing area characteristics.

This process enabled the evaluation of how proppants affect surface deformation, load distribution, and wear in downhole environments. The non-contact nature of the inspection ensured accurate results without damaging delicate embedment features.

Results & Value Delivered

- Detailed visualization of proppant embedment behavior

- Quantitative analysis of surface texture and bearing area characteristics

- Non-destructive testing methodology for fragile shale samples

- Insight into fracture performance to guide oil and gas engineering decisions

Conclusion

As the energy sector continues to optimize hydraulic fracturing techniques, understanding proppant behavior is more important than ever. EDM Intelligent Solutions delivers advanced metrology services tailored for embedment analysis in shale formations—helping researchers and engineers improve well productivity and reliability.

About EDM Intelligent Solutions

EDM Intelligent Solutions provides high-precision manufacturing and inspection services across energy, aerospace, medical, and scientific industries. Our advanced 3D Metrology platforms deliver accurate, repeatable measurements to support R&D, production, and quality control of critical components.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.