Aerospace Seal Slot Inspection Using High-Resolution 3D Scanning and Robotic Automation

Executive Summary

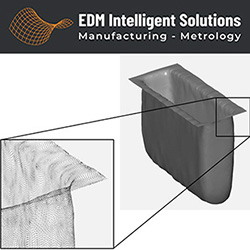

Seal slots in aerospace engine components are critical features that demand precise dimensional conformance and flatness to ensure proper sealing, thermal performance, and long-term durability. At EDM Intelligent Solutions, we apply high-resolution 3D metrology and automated inspection workflows to accurately evaluate these complex features on nickel alloy components. This report demonstrates our advanced 3D inspection process utilizing the RSH-M10 Robotic 3D Metrology System.

Overview of 3D Metrology Capabilities

Using advanced 3D scanning systems, EDM Intelligent Solutions performs micron-level inspection and dimensional analysis on a wide range of aerospace geometries. Our non-contact measurement process ensures accuracy without damaging delicate surfaces. Form, height, and flatness measurements are extracted with high fidelity and can be mapped to engineering datums for full GD&T evaluation.

Key capabilities include:

- Non-contact form and flatness measurement

- Automatic feature recognition and dimension extraction

- Alignment to datums for GD&T evaluations

- Automated scanning and data merging workflows

Application Case Study: Seal Slot Inspection

Component Overview

- Type: Engine Component

- Material: Nickel Alloy

- Metrology Service: Seal Slot Inspection

Seal Slot Inspection Process

In this example, a complex seal slot feature on a nickel alloy engine component was inspected using the RSH-M10 Robotic 3D Metrology System. The automated system performed full-area scanning of the slot and surrounding features. The process included automatic alignment to reference datums and data merging from multiple scan paths to ensure full coverage.

Once the scan was complete, automated feature extraction routines were used to isolate and evaluate slot width, depth, and flatness. The dimensional characteristics were analyzed in reference to a defined datum scheme to ensure full compliance with engineering specifications.

Results & Value Delivered

- Accurate, non-contact measurement of complex slot geometries

- Robotic automation enables consistent and repeatable inspections

- Dimensional data extracted in reference to datum alignment

- Enhanced confidence in quality control for critical engine features

Conclusion

Seal slot features in aerospace components are critical to engine reliability and efficiency. EDM Intelligent Solutions provides highly accurate and fully automated 3D inspection processes to validate these features without the risk of part damage or measurement uncertainty. Our robotic metrology systems bring automation and precision to even the most challenging inspection tasks.

About EDM Intelligent Solutions

EDM Intelligent Solutions specializes in precision electrical discharge machining and advanced 3D metrology services for aerospace, defense, and medical industries. We combine innovation and automation to support our customers’ most demanding component manufacturing and inspection requirements.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.