Advanced Components Carbide Sphere with Micro Through Hole – Form and Surface Deviation Inspection

Executive Summary

Precision components such as carbide spheres with micro through holes demand highly accurate dimensional validation to ensure proper performance in technical and scientific applications. EDM Intelligent Solutions provides advanced, non-contact 3D metrology services that inspect form and surface integrity at the micron level. This report details our automated inspection approach using the MVi5 3D Metrology Center to analyze the geometry and surface deviation of a carbide sphere with a through hole.

Overview of 3D Metrology Capabilities

Our non-contact scanning systems deliver µm-scale form measurement and surface analysis for complex parts of nearly any shape or material. Automated 3D capture and merge routines allow for efficient inspection of multiple components with minimal operator intervention.

Key capabilities include:

- High-resolution 3D scanning of small and spherical components

- Form analysis against CAD models for GD&T verification

- Surface deviation heat maps to identify imperfections

- Automated multi-part inspection using batch workflows

- Non-contact, non-destructive inspection ideal for brittle or delicate materials

Application Case Study: Carbide Sphere with Micro Through Hole

Component Overview

- Type: Carbide Sphere with Through Hole

- Material: Carbide Ball

- Metrology System: MVi5 3D Metrology Center

- Metrology Services: Form Inspection and Surface Deviation Analysis

Inspection Process

The carbide sphere was placed into the automated inspection routine of the MVi5 3D Metrology Center. Using multiple scan angles and automated merging, a complete 3D model of the part was generated with sub-micron precision. The geometry of the sphere and the micro through hole were compared against the nominal CAD model to identify form deviations.

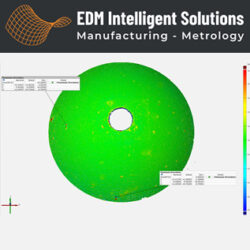

Surface deviation analysis was conducted across all critical areas to detect imperfections, inconsistencies, and machining defects. This process produced a color-coded deviation map and quantitative report for engineering review.

Results & Value Delivered

- Precise form validation of micro features on spherical components

- Clear identification of surface deviations through comparison with CAD

- Increased reliability in quality control for small, high-value components

- Automated batch processing reduces inspection time and operator effort

- Non-destructive method preserves fragile component integrity

Conclusion

Micron-level inspection of spherical components with micro features, such as through holes, requires precision, consistency, and non-contact methodologies. EDM Intelligent Solutions delivers all three through automated 3D scanning and CAD comparison workflows that provide robust data for design verification and manufacturing process improvement.

About EDM Intelligent Solutions

EDM Intelligent Solutions specializes in precision electrical discharge machining and 3D metrology services for advanced manufacturing industries. We support aerospace, medical, defense, and scientific applications with high-accuracy inspection solutions tailored to the most demanding specifications.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.