Aerospace Heat Exchanger Form and Flatness Inspection Using Non-Contact Optical Metrology

Executive Summary

As the demand for higher performance heat exchangers continues to increase across various high-tech industries, the geometry of these components becomes more intricate. New generations of thermal management devices now incorporate more complex and tightly spaced cooling fins to maximize performance within reduced physical space. Traditional tactile measurement tools face limitations in measuring such components without causing damage. Non-contact 3D optical metrology, however, offers a reliable and damage-free inspection method.

Overview of 3D Metrology Capabilities

EDM Intelligent Solutions uses cutting-edge non-contact 3D metrology equipment to measure components with highly complex geometries. Our robotic and 5-axis systems can quickly and accurately evaluate height, flatness, and pitch, ensuring quality and performance conformance for demanding applications.

Key capabilities include:

- Form and height measurement of intricate features

- Flatness evaluation of complex surfaces

- Pitch and spacing measurement for densely packed fin arrays

- Non-destructive, automated inspection processes

Application Case Study: Heat Exchanger Inspection

Component Overview

- Type: High Performance Heat Exchanger

- Material: Stainless Steel

- Industry Use: Aerospace, Medical, Defense, Scientific, and more

Inspection Process

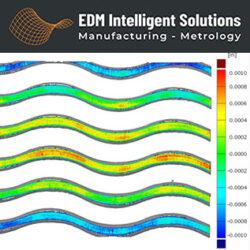

The component in this study, a high-performance stainless steel heat exchanger, required detailed inspection to confirm critical features such as fin height, flatness, and pitch. Due to the complex geometry and tight spacing between the fins, traditional tactile CMMs posed a risk of damaging the part or failing to capture accurate measurements.

Instead, the team utilized the RSH-M10 Robotic 3D Metrology System to perform a non-contact scan of the component. The system collected precise height and flatness data across the entire fin surface area. For added capability, the part could also be inspected using the Advanced 5-Axis CNC MVi5 3D Metrology Center, which provides flexibility and high-resolution measurements in complex orientations.

Results & Value Delivered

- Quick, automated verification of part geometry and surface conditions

- Non-destructive inspection of tightly spaced and fragile fins

- Reliable flatness and pitch analysis for performance assurance

- Enhanced product reliability through rigorous dimensional control

Conclusion

Advanced 3D metrology is essential in evaluating next-generation heat exchangers. EDM Intelligent Solutions’ non-contact inspection technology provides accurate, efficient, and damage-free measurement solutions for the aerospace and other demanding industries. Our combination of robotic and 5-axis systems ensures that even the most intricate thermal components are inspected with the highest precision.

About EDM Intelligent Solutions

EDM Intelligent Solutions is a leading provider of precision manufacturing and metrology services, specializing in electrical discharge machining, high-resolution 3D inspection, and custom automation. We serve the aerospace, medical, and defense sectors with commitment to quality and technological innovation.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.