3D Metrology Services – Aerospace – Heat Exchanger Form and Flatness Inspection

As the demand for higher performance heat exchangers continues to increase within the Aerospace, Automotive, Communications, Defense, Medical and Scientific industries, the features within them become increasingly smaller and more complex in an attempt to pack more cooling fin surface area into the same, if not smaller, overall device size. Advances in manufacturing including micro laser machining and additive manufacturing are allowing the fin design to begin to depart from the normal shapes and sizes that are common to previous generations of thermal management devices like heat sinks and heat exchangers. Due to their complex form and tight spacing between fins, traditional tactile measurement devices are challenged when it comes to measuring and inspecting (and not damaging) the new generation of ultra performance heat exchangers. This is where non-contact 3D optical metrology has a distinct advantage.

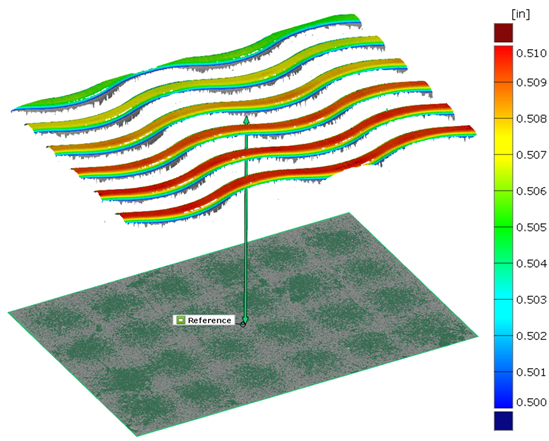

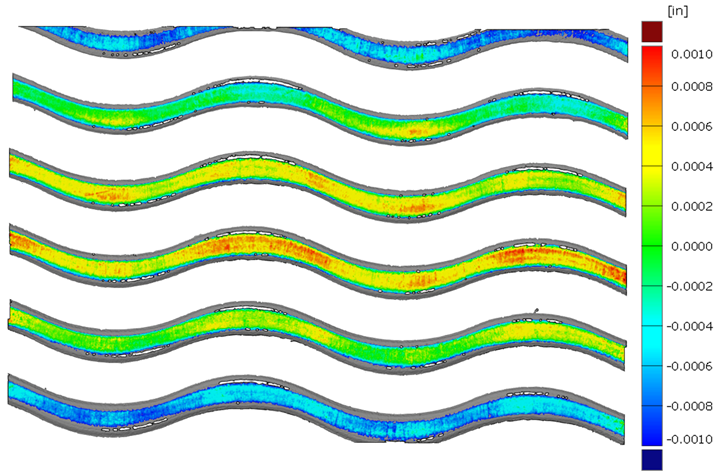

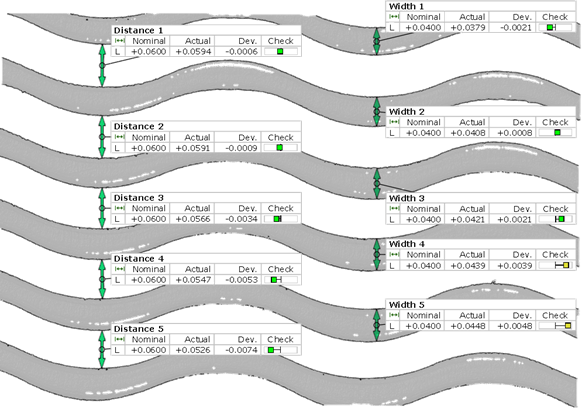

The team at EDM Intelligent Solutions utilizes unique non-contact 3D Metrology equipment to quickly and accurately measure components with intricate geometry of all shapes and sizes. This high performance heat exchanger was measured using our Form Measurement services. The height, flatness and spacing of the fins were easily confirmed using the RSH-M10 Robotic 3D Metrology System. The same measurements are also well suited for evaluation with our Advanced 5-Axis CNC MVi5 3D Metrology Center from EDM Intelligent Solutions. This automated inspection routine allowed for quick verification of part conformance to ensure efficiency and reliability of the final product.

Application Details

- Component – High Performance Heat Exchanger

- Material – Stainless Steel

- Metrology Services

- Form and Height Measurement

- Flatness Measurement

- Pitch Measurement

Fin Height Measurement

Flatness Measurement

Pitch Measurement Between Fins

COMPETITIVE 3D METROLOGY, MEASUREMENT, AND INSPECTION SERVICES

Intelligent solutions to manufacturing and measurement challenges are what we do. Over the past 25 years, we’ve completed thousands of measurement and metrology projects. What differentiates EDM Intelligent Solutions 3D Metrology services from the competition is our unique understanding of each manufacturing process. The EDMIS metrology technicians and applications engineers support their colleagues in our tight tolerance CNC machine shop that produces ultra-precision components for customers every day. Harnessing this unique relationship with manufacturing, our metrology team has the experience needed to fully assist our customers leverage the measurements taken of their components to improve their manufacturing processes. We are confident that we can measure your most challenging components and work with you to fully understand what those measurements tell you about them. To learn more about how EDMIS can help you, contact our metrology team with your request for quote.