What is Surface Roughness?

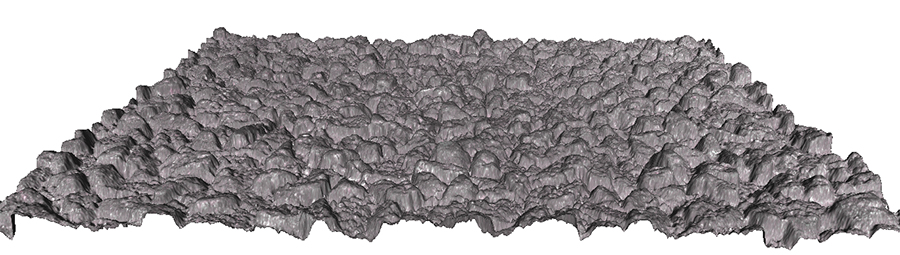

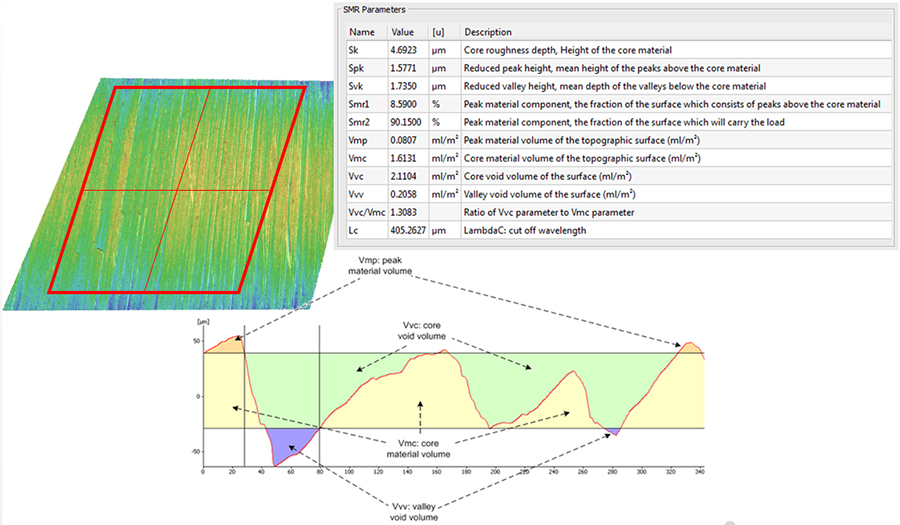

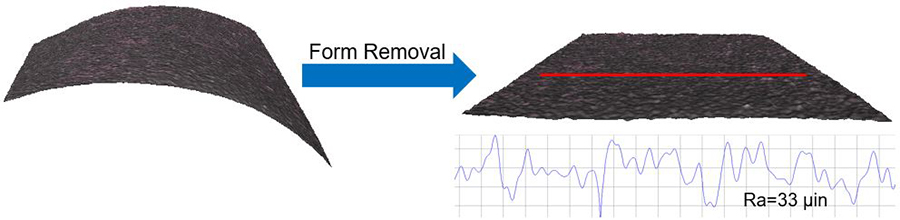

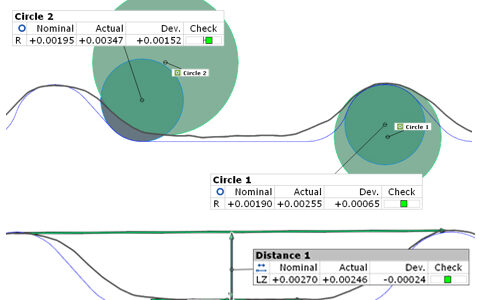

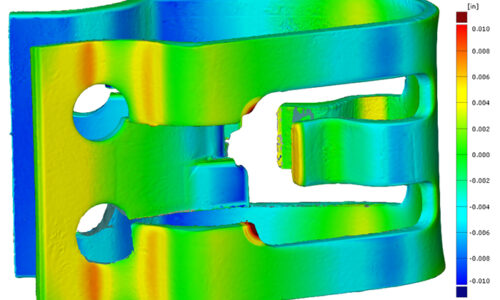

Surface roughness itself is defined as the frequency of peaks and valleys in the base material of a surface. In machined parts, the surfaces are composed of complex shapes made of a series of peaks and valleys of widely varying heights, depths, and spacing. The surface roughness is affected by the asperities of that surface. Surface texture measurement is a critical, yet often overlooked, aspect of any manufacturing project.

What is Surface Roughness Measurement?

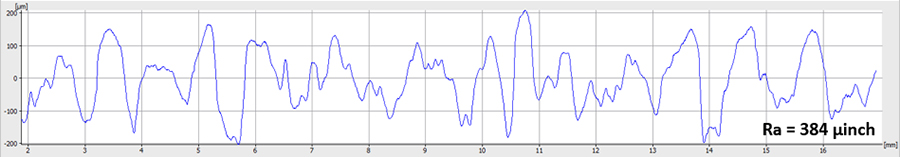

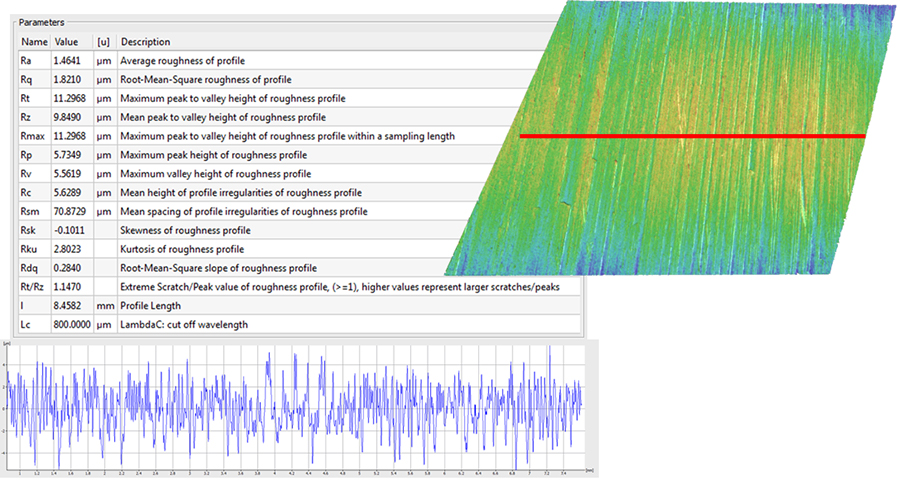

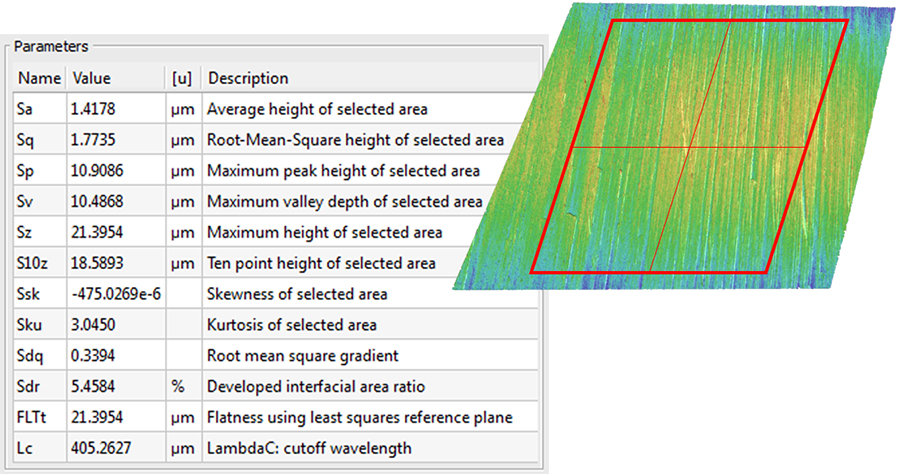

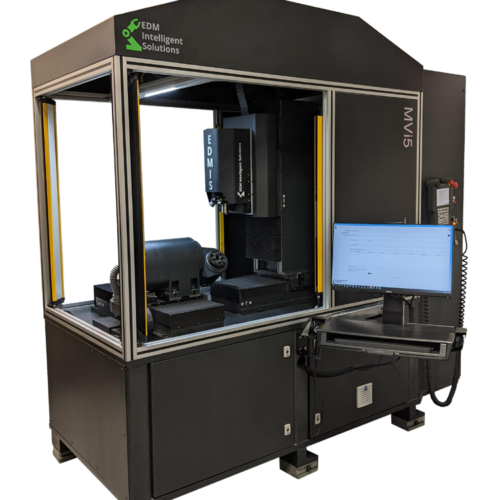

Surface Roughness Measurement both characterizes and quantifies a surface. Surface finish callouts are typically listed as requirements on engineering drawings along with the other dimensions and tolerances of a part. These surface roughness measurement values are calculated using a surface roughness tester, called a 3D surface profilometer, and are expressed as a single numeric parameter, Ra, if the calculation involves calculating the roughness of a part’s linear profile or Sa if it involves the roughness of a parts full surface area.