MACHINING THE IMPOSSIBLE – PRECISION GRINDING SERVICES

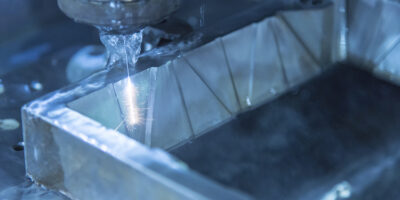

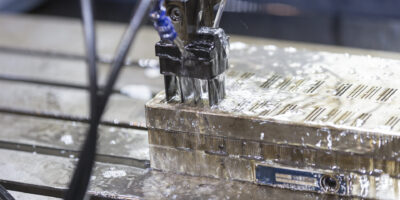

Precision Grinding not only supports our electrical discharge machining processes like Wire EDM and Sinker EDM, it is also offered as a stand-alone service to our customers in a wide range of industries. Our tight tolerance form grinding and surface grinding machines are capable of producing extremely accurate dimensions through the process of removing microns of material at a time. Advanced construction ensures consistent cutting performance and production of quality components.

WHAT IS PRECISION GRINDING?

In the precision grinding process a rotating abrasive wheel is used to smooth the surface of a workpiece which is typically a flat plane. Parts made of ceramic, metal or plastic materials are well suited to this process which produces and extremely smooth and flat surface by removing a very thin layer of the material with each pass of the abrasive wheel. The grinding machine is built around a motorized spindle holding an abrasive wheel. Below it sits a workholding device, normally a magnetic chuck. The chuck holds the workpiece in a static location while it is being worked on. The abrasive grinding wheel is then passed over the surface of the workpiece while being lowered closer and closer to the workpiece with each pass. This extremely controlled adjustment of the amount of material cut with each pass allows for tight tolerances to be achieved. To produce highly accurate forms in the workpiece, the abrasive wheel can be easily shaped through a process known as wheel dressing.