MACHINING THE IMPOSSIBLE – LASER ABLATION SERVICES

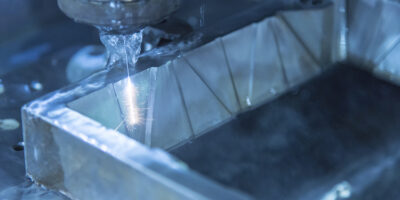

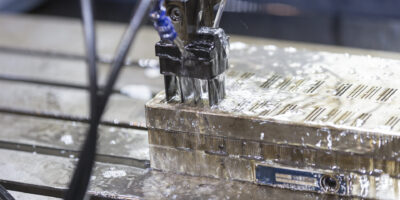

EDM Intelligent Solutions offers a very unique manufacturing process known as Laser Ablation that allows for precision machining of the nonconductive materials that are not compatible with electrical discharge machining. This includes ceramics, diamonds, glass and even plastics. Complimenting our Wire EDM and Sinker EDM processes, Laser Ablation is the preferred alternative to conventional CNC machining methods for which extremely hard, nonconductive materials would require the use of costly diamond coating CNC milling tools. Since the “cutting tool” of Laser Ablation is a beam of light, the added benefit of this type of machining is that there is no physical contact ever made with the workpiece. Our 5-Axis CNC laser ablation machining centers are capable of cutting with laser beams smaller than the diameter of a human hair. Advanced thermally stable construction of each machine ensures consistent cutting performance and production of quality components. Scalable machine tending robotic automation integrated with our CNC laser machines allows for continuous production to run around the clock, lights out.

WHAT IS LASER ABLATION?

The laser ablation process uses a highly focused laser beam to remove material from solid surfaces by irradiating the base material to a point that it evaporates, sublimates or is converted to a plasma. The laser beam can be controlled in a manner where short pulses remove the material so quickly that the surrounding material absorbs very little heat, preventing thermal distortion in the base material. This unique process allows EDM Intelligent Solutions to produce intricate shapes, extremely sharp cutting edges and accurate holes in all types of nonconductive materials. Our laser cutting machines are designed for the highest levels of accuracy and incredible reliability. Leveraging integrated automation to increase productivity makes Laser Ablation a perfect option for projects requiring the use of nonconductive materials and quantities ranging from just a few all the way up to high volume production applications requiring thousands of pieces.