Production Solutions Designed for Manufacturability

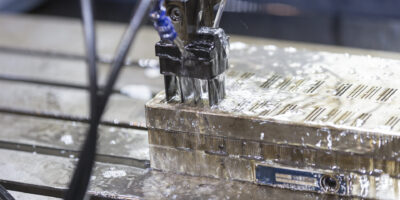

EDM Intelligent Solutions offers contract EDM manufacturing services. We are here to assist with your production manufacturing needs. In our modern, fully-tooled CNC machine shop, we produce even the most complex parts consistently and with high reliability. Because of our in-house manufacturing machine development expertise, we are able to build modular, scalable production equipment cells that ensure a quick response to rapid changes in the market forecast. This minimizes capital costs and easily allows your production levels to match the market demands. We are an ISO9001:2015 and AS9100D certified company and we are ITAR registered, ensuring that your project will be completed to your precise specifications and will meet your quality requirements, on time, and within budget.

EDMIS Contract Manufacturing Services

supporting prototype quantities through full scale production

Engineering

We have in-house, experienced engineering support staff to complement our manufacturing and production teams.

Process

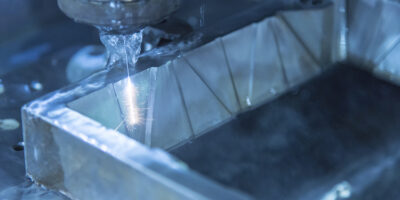

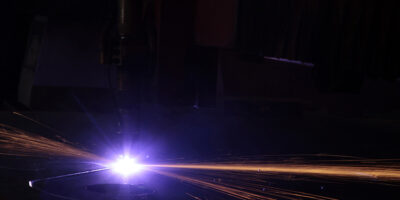

Our decades of experience in combining established manufacturing processes with innovative technologies help to keep our ongoing development of technologies relevant with future advances in manufacturing.

Technologies

Highly accurate manufacturing technologies coupled with unique 3D Metrology and Measurement offer the most advanced contract manufacturing solutions.

Partnerships

We partner with our customers to fully understand their market needs and production requirement so we can provide the highest levels of service and accommodate changes rapidly.

Industries

As a leading contract precision CNC machine shop centrally located in Illinois, companies nationwide choose EDMIS as their manufacturing partner.

We produce components to the highest standards commonly required by the Aerospace, Automotive, Communications, Defense, Medical and Scientific industries.

Compliance

We are an ISO9001:2015 and AS9100D certified company and we are ITAR registered. Our Quality Management System ensures that all projects are held to the specific requirements flowed down to us by our customers.