The EDMIS Micro Milling Advantage

At EDM Intelligent Solutions (EDMIS), precision is our foundation. For more than 25 years, we’ve specialized in tight-tolerance manufacturing and 3D metrology, helping manufacturers, researchers and engineers across aerospace, medical, defense, automotive and electronics industries push the boundaries of what’s possible in micro-scale production and micro EDM machining.

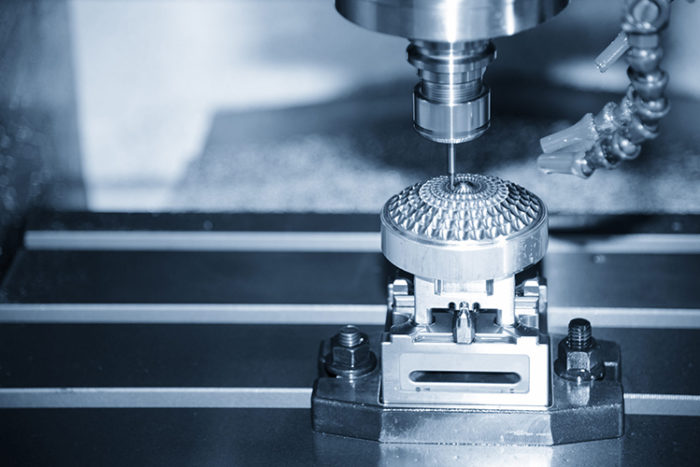

Our advanced micro milling services deliver the accuracy, repeatability and surface finishes required for today’s most demanding applications. From prototype to production, we combine deep manufacturing expertise with proprietary measurement systems to ensure every part meets the highest standards of quality and performance.

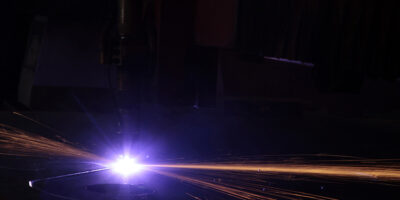

When to Choose Micro Milling Over Other Machining Methods

While electrical discharge machining (EDM), laser ablation and conventional CNC milling each have distinct strengths, micro milling often delivers the ideal combination of accuracy, flexibility and surface quality, especially for components that demand exact geometry and repeatable detail at the micron level. You may choose micro milling in specific applications, such as:

1. When Parts Require Ultra-Fine Detail and Sharp Edges

Micro milling excels at producing small, intricate geometries that traditional milling might struggle to achieve cleanly. For example, medical implants, miniature gears and microfluidic channels often require edge sharpness and surface finishes that cannot tolerate recast layers or heat-affected zones. Micro milling removes material mechanically, maintaining the original material properties and crisp edge definition.

2. When You Need Superior Surface Finish Without Post-Processing

Micro milling can achieve surface finishes as smooth as Ra 0.05 µm, minimizing or eliminating secondary finishing operations. This makes it an ideal choice for optical components, sealing interfaces and medical tools that must be ready for use right off the machine.

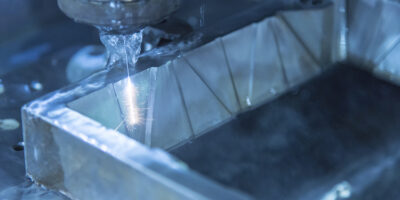

3. When Heat Sensitivity or Material Integrity Is a Concern

Since micro milling is a mechanical removal process, it generates minimal heat and maintains the material’s metallurgical structure. This makes it particularly well-suited for heat-sensitive alloys, polymers and composites used in aerospace and electronic applications.

4. When Dimensional Accuracy Must Be Verified During Production

Unlike many traditional machining processes that rely on post-process inspection, EDMIS integrates real-time 3D metrology directly into its micro milling workflow. That means each feature can be verified and adjusted during machining rather than after. This level of precision control ensures consistent accuracy across production batches.

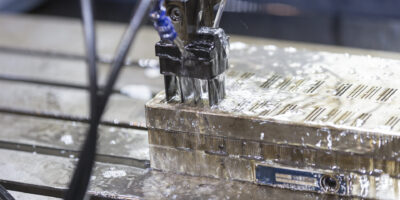

5. When Speed and Efficiency Are Top Priorities

Micro milling’s flexibility and automation capabilities often translate to faster turnaround times. By combining rapid spindle speeds, automatic tool changers and robotic part handling, EDMIS achieves efficient, 24/7 production without compromising quality. For customers balancing tight delivery schedules and complex designs, micro milling can reduce total production time and overall cost compared to slower operations.

6. When You Need Complex Multi-Material or Hybrid Components

For assemblies that use micro milling materials or combine different materials, such as metal-to-ceramic interfaces or conductive inserts within insulating housings, micro milling offers adaptive feed control and fine toolpath programming to ensure that transitions remain accurate and free of mechanical stress, even in difficult-to-machine combinations.

At EDM Intelligent Solutions, we guide every customer through the process of determining the best machining method for their part’s geometry, tolerances and performance goals. Because EDMIS offers a full spectrum of precision machining services, we can recommend the process, or combination of processes, that achieves optimal results for your design.