EDM Hole Drilling Services

EDM Intelligent Solutions (EDMIS) offers EDM Precision Hole Drilling services designed to meet the needs of various industries. Our unmatched expertise in electrical discharge machining enables us to deliver high-accuracy holes in a wide range of conductive materials, making us a preferred partner for R&D and contract manufacturing projects.

MACHINING THE IMPOSSIBLE – EDM HOLE DRILLING SERVICES

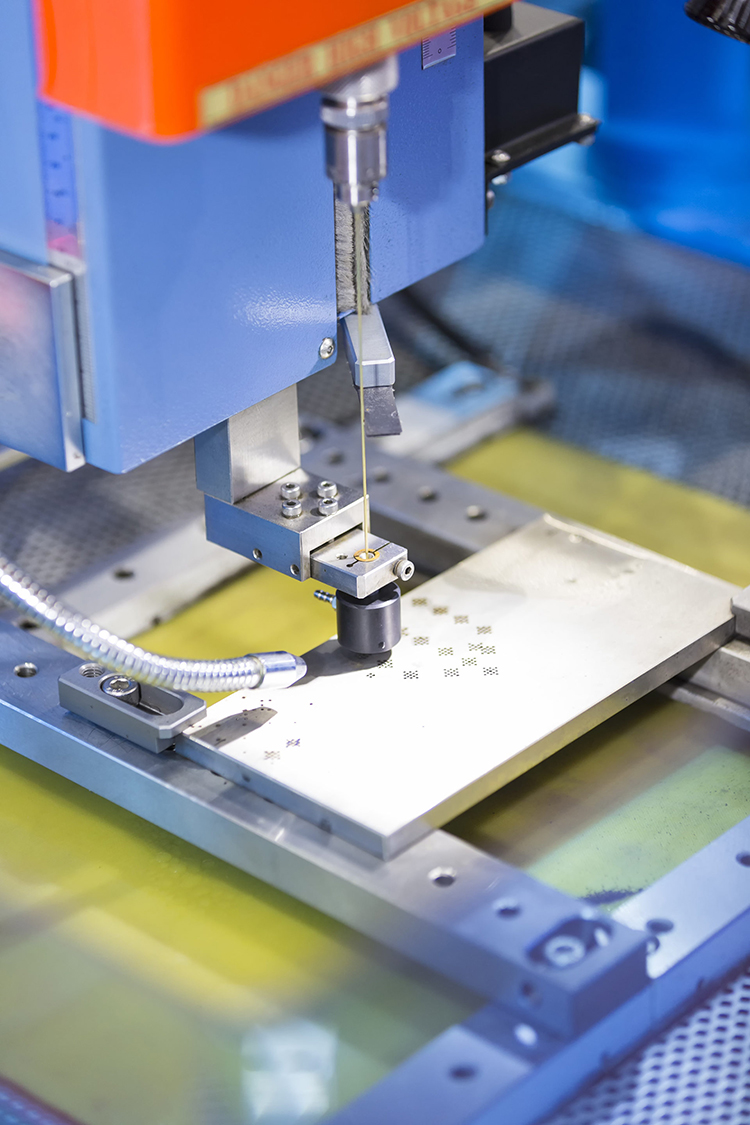

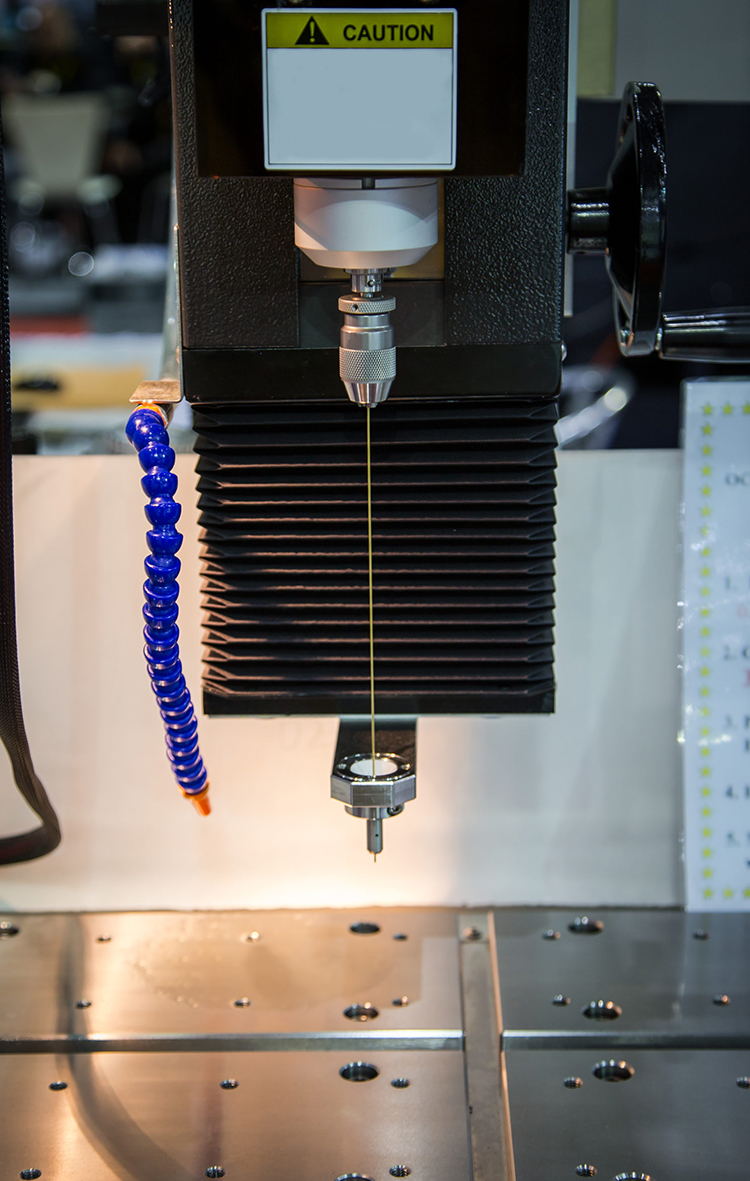

EDM Intelligent Solutions provides specialized EDM Hole Drilling services, capable of creating both blind and through holes with precision. Our purpose-built CNC-operated EDM holepopping machines can produce holes as small as 300 microns (0.0120 inches) in some of the toughest conductive materials, like carbide and nickel.

Through advanced EDM generator technologies and high-quality electrode materials, we achieve high-precision hole sizes, outstanding hole edge quality, excellent surface finishes and an overall improvement in part accuracy and hole consistency.

EDM HOLE DRILLING OVERVIEW

Our Small Hole EDM Drilling services leverage advanced technology and decades of experience to provide reliable and efficient solutions.

WHAT IS EDM HOLE DRILLING?

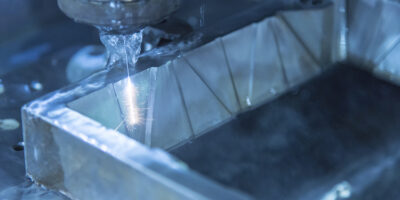

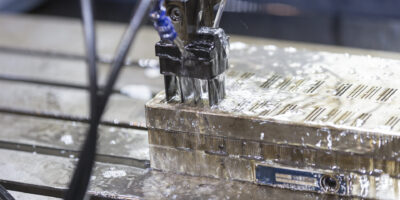

Like Sinker EDM, electrical discharge machine hole drilling relies on electric current to remove material. A pipe-shaped electrode conducts the current directly to the workpiece, causing it to erode or “burn away” conductive materials. The electrode doesn’t ever touch the machined material, so the deflection of the pipe electrode is minimized when compared to drilling holes with a traditional cutting tool.

During EDM Holepop, the tube electrode is energized and spun at high speeds while high-pressure flushing is pumped through the tube to flush out the workpiece material being cut away. This technique enables EDM Intelligent Solutions to drill holes quickly and precisely in various conductive materials.

Our EDM Drilling machines are designed for the highest accuracy and incredible reliability. They feature uniquely integrated automation that offers increased productivity, making EDM Hole Drilling the perfect choice for projects with hole quantities ranging from just a few to high-volume production applications requiring thousands of holes.

EDM HOLE DRILLING CAPABILITIES

Drilling accurate and repeatable holes in extremely hard materials is no easy process. Leveraging decades of expertise in tolerance Sinker EDM, our team excels at machining holes in some of the most challenging conductive materials.

For 25 years, we have been offering standard tolerances (0.0010 inches to 0.0005 inches) and high-precision tolerances as tight as 0.0001 inches (2 microns) for an array of industries and applications. Our 3-axis and 5-axis CNC hole drilling electrical discharge machinery can run multiple pipe electrode sizes, ranging from 0.3mm (0.0120 inches) to 4mm (0.1575 inches) in diameter.

We partner with suppliers worldwide to ensure continuous access and timely delivery of hole-popping electrodes made to our exacting requirements from various standard and exotic materials. This ensures that our EDM hole poppers are never left waiting for pipe electrodes to arrive while the drilling process is active around the clock.

Extreme machining efficiencies are possible due to the integrated automation that changes both pipe electrodes and workpieces without human intervention. This enhances overall productivity and saves our customers’ time and money. Our decades of EDM machining experience and state-of-the-art equipment enable us to provide repeatable quality parts and components from any conductive material.

We are continuously working with our technology partners to upgrade our CNC EDM hole drilling capabilities to meet the ever-evolving needs of our diverse customer base. We also complement our EDM Precision Hole Drilling capabilities with other manufacturing services like Precision Grinding, Micro Milling and 3D measurement of machined components for full quality assurance.

EDM Hole Drilling Specifics:

- Advanced 3-axis and 5-axis CNC Hole Drilling EDMs built for efficient, 24/7 operation

- Multiple pipe electrode materials are used like brass, copper and tungsten

- Workpieces up to 4 inches thick are easily machined using EDM Hole Drilling

- Standard machining tolerances of 0.0010 inches to 0.0005 inches and high precision tolerances as tight as 0.0001 inches (2µm micron)

- Small Hole EDM machines with tolerances as precise as 1 micrometer (µm) and below

- Feature aspect ratios up to 38:1

- Finished EDM drilled hole diameters ranging from 0.3mm (0.0120 inches) to 4mm (0.1575 inches)

- Hole diameters as small as 40µm through fine (micro) EDM drilling

- Surface finishes down to 4Ra µin (micro inches), eliminating the need for additional finishing or polishing

- Small batch production of 1-50+ pieces

- Contract manufacturing of full production quantities of thousands of pieces

EDM HOLE DRILLING MATERIALS

EDMIS strives to meet your specific needs. Through strategic sourcing partnerships with a vast array of qualified material suppliers nationwide, we can manufacture your components from whichever materials you require. Strict quality standards are met by all vendors and material suppliers to EDM Intelligent Solutions to ensure that the components we produce can meet the highest standards commonly required by the aerospace, medical, automotive, defense, communications and scientific industries.

Regarding materials, EDM Hole Drilling is compatible with many metals that conventional machining, like milling and turning, cannot handle. This process can easily machine hardened materials such as tungsten carbide. Using energized pipe electrodes also makes EDM Hole Drilling gentle for softer metals like copper. Even the most delicate ultra-thin materials are machined with precision, as the electrode never touches the workpiece, minimizing the risk of damage.

EDM Hole Drilling Compatible Materials

EDM Intelligent Solutions has completed thousands of EDM Hole Drilling projects using a diverse set of materials including those listed below. Don’t see your specific material on the list? Contact us to determine if that material can be cut using CNC Electrical Discharge Machining and how EDMIS can source that material for you.

- Aluminum

- Brass

- Copper

- Exotic Metals

- Molybdenum

- Titanium

- Tungsten

- Carbide

- Tool Steels

- A-2, A-5, A-6, A-8

- D-2, D-3, D-5

- DC-53

- H-11, H-12, H-13, H-19

- L-6

- M-1, M-2, M-3, M-4, M-42

- O-1, O-6

- S-1, S-7

- T-1

COMMON EDM HOLE DRILLING APPLICATIONS

When components require extremely accurate and deep blind holes and/or through holes, EDM Hole Drilling should be considered. EDM Hole Drilling services are well suited for parts requiring intricate tolerances, material stress and thermal heating limitations and those needing superior surface roughness finishes.

Sinker EDM Hole drilling is sometimes the only machining method that can produce quality holes when a design requires too hard or too brittle materials. Conventional machining methods like CNC drilling will wear out many drills for just a few holes while EDM Hole Drilling pipe electrodes can produce hundreds of holes each. Through integrated machine automation, the quantities of parts being completed can easily be scaled up to meet the high volumes required by some of our largest customers.

This is just a small sample of all the components that EDM Intelligent Solutions has manufactured using our advanced EDM Hole machining processes. There aren’t many types of parts that we have not worked on in some form over the last 25 years serving these industries. No project is too large, too complex or too precise for EDM Intelligent Solutions, making us the top choice for leading OEM manufacturers nationwide. To learn more about how EDMIS can help you, contact our manufacturing team with your request for a quote.

Sample EDM Hole Drilling Applications

- Interconnect Components – holes for electrical contacts

- Fiber Optic Components – holes for glass fiber optics

- Medical Components – holes for drug delivery systems, surgical implants and tooling

- Optical Lenses – holes lens arrays and assemblies

- Research & Development – holes for particle sensors and accelerator components

- Aerospace Industry – holes in jet engine turbine blades for cooling and fuel nozzle holes

- Automotive Industry – holes in fuel injectors

- Plastic Injection Molding – holes used as venting for injection molds

- Cutting Tool Industry – holes used for inline through the tool liquid cooling and flushing

Competitive Electrical Discharge Machining Solutions

As our name suggests, EDM Precision Hole Drilling is one of our main service offerings. For over 25 years, we have delivered exceptional results on thousands of EDM Hole drilling projects. We stand out in the manufacturing industry by offering micron-level tolerances while maintaining globally competitive pricing and fast turnaround times.

Why Choose EDM Intelligent Solutions?

Choose EDM Intelligent Solutions for your EDM Hole Drilling needs and benefit from our competitive advantages, which include:

- Comprehensive solutions: We offer a full suite of services, meeting all your manufacturing requirements under one roof.

- Outstanding customer satisfaction: Our dedication to meeting customer needs and maintaining high satisfaction levels drives us to improve and adapt to our clients’ evolving requirements continuously.

- Unparalleled quality assurance: We are an ISO9001:2015 and AS9100D certified company, demonstrating our commitment to stringent quality management systems and adherence to various industry standards.

- 24/7 reliability: Our machines are built for uninterrupted operation. We offer 24/7 production capabilities to meet even the most demanding deadlines. Our advanced equipment seamlessly scales production volumes from small batches to high-volume manufacturing runs.

Contact Us Today for a Quote

Utilizing our vast knowledge of EDM Hole Drilling techniques and decades of industry experience, we are confident that we can produce your most challenging components to your exact specifications. To learn more about how EDMIS can help you, contact our manufacturing team with your request for a Precision Hole Drilling quote.