Manufacturing Services – Energy – RF & Microwave Components

Custom Manufactured RF and Microwave System Components

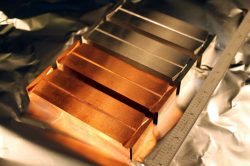

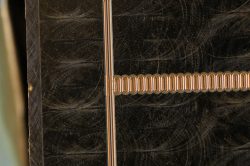

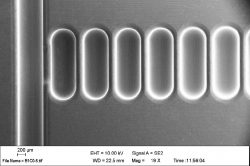

We’re known for manufacturing unique and custom RF and Microwave components that are used for industrial inspection, microwave telecommunications, military electronic warfare systems, medical imaging, radar systems, satellite and space communications, and weather systems. The components that we manufacture for our customers are commonly used in RF and microwave systems that operate in frequencies ranging from 75 GHz to 300 GHz. Some of these components are even being used in applications that operate at THz frequencies at national laboratories like SLAC National Accelerator Laboratory.

Utilizing our tight tolerance, high precision manufacturing processes like micro milling, laser ablation and 3D metrology along with specialized Ultra High VAC and clean handling processes, we possess the necessary capabilities to manufacture RF and microwave components of the highest complexities with the most stringent requirements.

|

|

|

|

Common RF and Microwave Components

- Waveguides

- Traveling Wave Tubes

- Ladders

- Circuit Blocks

- Circuit Guns

- Coupler Blocks

- Klystron Components

- Adapter Plates

- Helices

- Windows

- Flanges

- SLAC Hybrid Flanges

- Cold Test Circuits

- Vacuum Envelope Assemblies

- Brazing Fixtures

- Bonding Fixtures

Common Materials Used for RF and Microwave Components

- OFE C101 Copper (Cu)

- OFHC C102 Copper (Cu)

- C107 Copper Silver (CuAg)

- Amzirc

- Glidcop

- Molybdenum (Mo)

- Tungsten (W)

- Stainless Steels

COMPETITIVE ELECTRICAL DISCHARGE MACHINING SOLUTIONS

As our name suggests, EDM machining is one of our main service offerings. Over the past 25 years, we’ve completed thousands of Wire EDM projects. What differentiates EDM Intelligent Solutions manufacturing services from the competition is our ability to not only hold micron tolerances but to do so while still offering globally competitive pricing and lead times. Utilizing our vast knowledge of EDM techniques and decades of industry experience, we are confident that we can produce your most challenging components to your exact specifications. To learn more about how EDMIS can help you contact our manufacturing team with your request for quote.