Machining the Impossible – Micro Milling Services

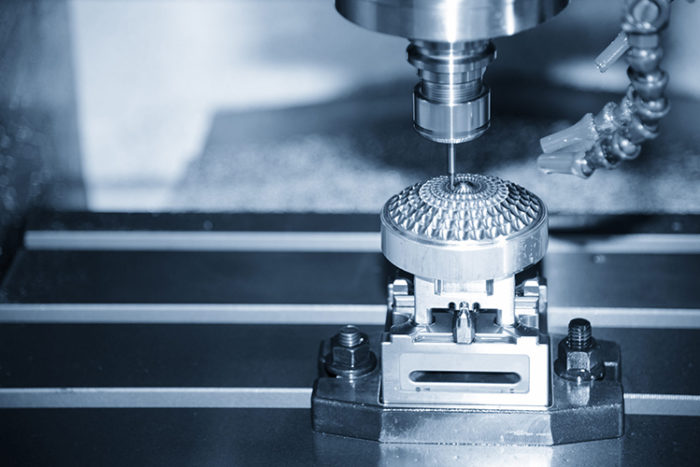

Micro Milling not only supports our electrical discharge machining processes like Wire EDM and Sinker EDM, it is also offered as a stand-alone service to our customers in a wide range of industries. Our 3-Axis CNC mills are capable of cutting with tools smaller than the diameter of a human hair. Advanced thermal controls integrated directly into the structure of our 3-Axis milling machinery ensure consistent cutting performance and production of quality components. Scalable machine tending robotic automation tied to each 3-Axis CNC mill allows for continuous production to run around the clock.

What is Micro-Milling?

While very similar in motion to larger 3-Axis CNC milling machines where the cutting tool moves across the X, Y, and Z linear axes, micro-milling machines construction differs by using an extremely stiff frame design, enhanced guideways systems, advanced thermal controls, ultra-responsive servo motors, extremely high speed motorized spindles and world-class industrial CNC controls. These specific differences set micro-milling machines into a complete class of their own which allows them to achieve micron level accuracy, repeatability and surface finishes that no standard CNC milling machine can match. Micromilling machines can produce features smaller so small that high power magnification is required to even see them.