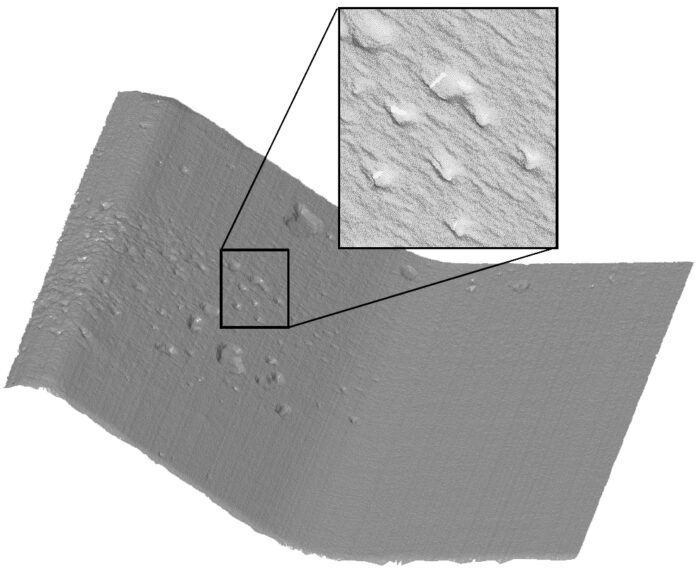

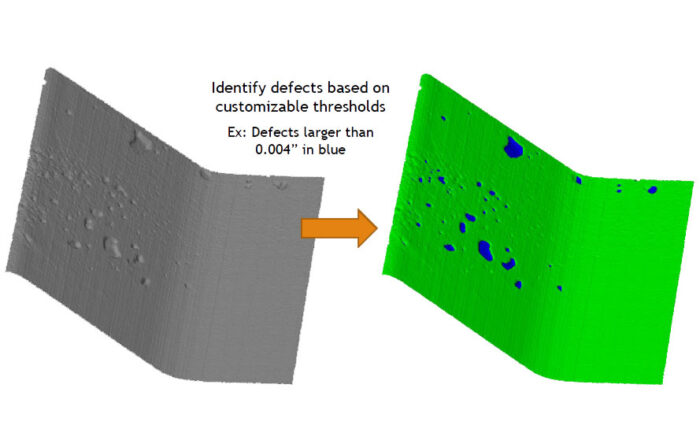

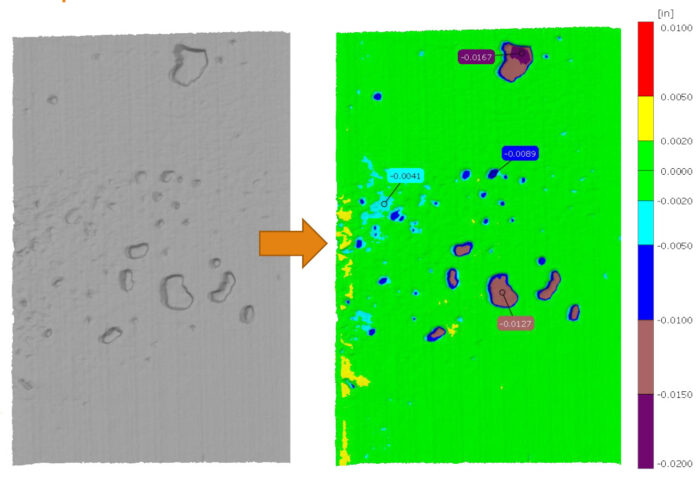

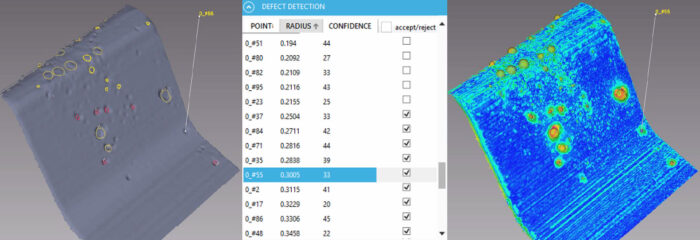

At EDM Intelligent Solutions, our high-resolution 3D scans of piece parts allow for form measurement down to the µm scale. Form measurements are made by cutting profiles across the 3D part scan data set and those included points are used to gather various form dimensions including radii, angles, slot width, height step and more. This ability to measure the 3D data allows us to also search for defects within the scanned surface.

Below is an example of defect detection that was completed on a molded plastic shell for a piece of medical equipment. 3D measurements can easily detect defects on the surface of nearly any part and are less susceptible to lighting issues than images captured with traditional 2D cameras. The defect scan and 3D measurements of this component were completed using our RSH-M10 Robotic Metrology System. This is a three-step process.

APPLICATION DETAILS

- Component – Medical Equipment Shell

- Material – Molded Plastic

- Metrology Services:

- Form Measurement

- Defect Detection