Essential Role of 3D Metrology & Inspection Services in Aerospace MRO

Aerospace Maintenance, Repair, and Overhaul (MRO) is the critical backbone ensuring that aircraft, engines, and vital aerospace components remain safe, airworthy, and operational throughout their service life. Keeping the global aviation industry—from commercial airlines to military forces—flying safely and reliably depends on precise, traceable inspection.

At EDM Intelligent Solutions, our 3D Metrology Systems and Precision Measurement Services are integral to your Aerospace MRO processes. Our technology provides the essential inspection data you need to accurately determine if an aircraft component requires repair and, critically, to verify its suitability for safe return to service after that repair.

Highly Accurate 3D Measurement for Critical Aircraft Components

Our specialized MVi5 3D Metrology Centers and RSH-M10 Robotic Metrology Systems are used to measure a myriad of components across the entire aircraft.

- Aero Engine MRO: We provide precise measurement of engine components after thousands of hours on-wing, including critical hot section parts.

- Avionics & Airframe: Measurement of complex avionics sensors and other critical airframe components after years of demanding operations.

Inspection systems and on-demand, quick turnaround measurement services from EDM Intelligent Solutions enable our MRO partners to achieve unprecedented safety, efficiency, and traceability—factors critical to keeping today’s modern aircraft flying.

Automated Defect Detection for Specialized Aero Engine Repair

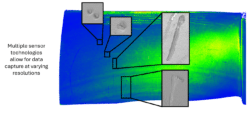

Our Defect Detection Process Solution (DDPS) is specifically designed for specialized Aero Engine Repair and Overhaul facilities. This system doesn’t just inspect critical turbine engine hot section components; it finds and measures defects in full 3D.

This delivers MRO inspection teams with fully automated, objective, and traceable measurements that can be used to plan the most effective repair course in an expedited manner, minimizing aircraft downtime.

This delivers MRO inspection teams with fully automated, objective, and traceable measurements that can be used to plan the most effective repair course in an expedited manner, minimizing aircraft downtime.

Reverse Engineering for Component Sustainment

Major aircraft platforms are often in service for decades. Sustainment of these assets can be challenging when OEM parts become unavailable over time.

Our high-resolution metrology 3D scanning and metrology systems allow MRO operators to reverse engineer replacement parts for critical aircraft components that are no longer produced by the Original Equipment Manufacturer (OEM). This capability is vital for long-term fleet sustainment and operational readiness.