Return on investment varies by production scale and usage frequency. Factors include reduced inspection labor, faster cycle times, fewer rejected parts and improved customer compliance. Some benefits, such as time saved and more detailed analysis, are immediate, driven by the accuracy and consistency of automated data.

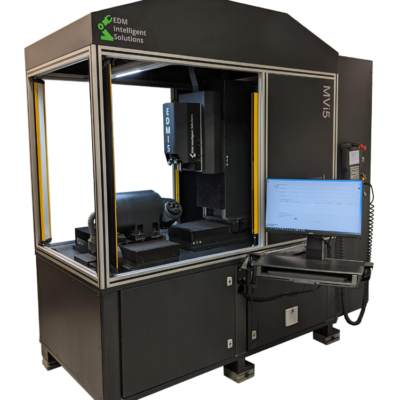

3D Metrology Systems – Full Details

EDM Intelligent Solutions: 3D Metrology Systems Group

The systems group at EDM Intelligent Solutions (EDMIS) offers automated optical inspection, dimensional metrology, dimensional inspection, and surface roughness measurement solutions, including industrial 3D metrology centers and robotic metrology systems for in-line and near-line production measurement applications. Our CNC-based inspection machinery provides innovative solutions for engineering process development and automated quality monitoring of advanced manufacturing and production processes.

Specialized 3D Metrology Services for Manufacturing Industries

Automated 3D Metrology Systems from EDM Intelligent Solutions are at work 24/7, supporting OEM customers and manufacturing service providers within the major Aerospace, Automotive, Communications, Defense, Medical and Scientific industries.

What Is 3D Metrology?

3D Metrology is the scientific study of physical measurements. In the context of manufacturing, it encompasses precision measurement of tools, fixtures and machined components. It is used for measuring length, distance and height (three axes x, y, z), by acquisition of geometric surface points of an object, providing infinitely more data than conventional measurement methods. These measurements are often acquired through the use of a coordinate measuring machine (CMM). However, new advances in optical sensor technologies are empowering the evolution of 3D metrology techniques that no longer rely on CMMs.

Dimensional Metrology and Surface Roughness Measurement

Each metrology system from EDMIS provides in-depth, non-contact 3D measurement and inspection of components with almost any shape, size, form and surface roughness. The dimensional metrology and surface finish test reports that are created by the EDMIS metrology systems are used to improve engineering processes and control the quality of full-scale manufacturing and production

Simple and Secure User Interface

Featuring an easy-to-use system control software graphical user interface (GUI) known as EDMISi, each 3D metrology system is ready to support Operators, Engineers and Managers who require a simple and trusted measurement solution. The integrated online programming environment within the EDMISi makes quick work of measurement routine creation. Built-in collision avoidance functionality verifies that each measurement program is free of potential collisions between the workpiece and metrology system. Dimensional measurements and surface roughness testing results are automatically completed and output to the user via the Feature Extraction module within the EDMISi interface. Simple pass/fail reports are available along with in-depth engineering study reports used for process improvement.

Standard Systems and Customizable Metrology Platforms

Our full range of standard metrology platforms can be customized to meet the specific measurement requirements of our customers’ applications while allowing for easy integration of the systems within their existing production environments.

Whether this involves machine tool manufacturing intelligence software, machine tending robot arms, custom workholding fixture tooling, integration with existing CAD/CAM packages or additional safety equipment like hard doors and fencing, EDMIS works with each customer to make their technology adoption process seamless.

If you have any questions about our Intelligent Solutions for 3D metrology and manufacturing or are interested in learning more, contact us now!

EDM Intelligent Solutions: FANUC Authorized Systems Integrator

We are proud to be an official FANUC Authorized Systems Integrator incorporating industry proven FANUC Robotics and FANUC CNC products within our unique 3D Metrology solutions. This partnership with FANUC America Corporation empowers the team at EDM Intelligent Solutions with the factory-level training, extensive automation know-how and enhanced technical experience to effectively integrate FANUC Robotics, CNC and motion control systems.

NAICS Code 334519 Classified

3D Metrology Systems from EDM Intelligent Solutions

Competitive 3D Metrology Systems and Equipment

We create intelligent solutions for manufacturing and measurement challenges. Over the past 25 years, we’ve completed thousands of measurement and metrology projects. What differentiates EDM Intelligent Solutions 3D Metrology Systems from the competition is our team’s unique understanding of how our systems can be applied to almost every manufacturing process.

Complete 3D Metrology Solutions for Complex Measurement Challenges

The EDMIS team of metrology technicians and applications engineers supports its colleagues in our tight tolerance CNC machine shop that produces ultra-precision components for customers every day. Harnessing this unique relationship with manufacturing, our metrology team has the expertise needed to fully assist our customers in integrating EDMIS metrology systems, leveraging 3D measurements to enhance both their manufacturing processes and products. We are confident that we have a system that can measure your most challenging components and we are ready to work with you to fully understand your metrology needs. To learn more about how EDMIS can help you, contact our metrology systems team with your request for a quote.

Frequently Asked Questions About Industrial Metrology Systems

Review these frequently asked questions regarding industrial metrology systems and our capabilities.

High-precision 3D metrology systems often get close to the nearest micron or millimeter. However, the results for your project depend on configuration and part geometry. Speak with a representative for a clearer vision of what you can expect with our services for aerospace, medical, defense and other applications.

Optical metrology eliminates the need for physical contact. Some clients prefer optical metrology for its high-resolution detail, automation and non-destructive capabilities. EDMIS industrial metrology equipment can also detect surface details in a single scan.

Traditional CMMs are better suited for challenging surfaces that are reflective or transparent. CMMs also prevent the risk of collisions when collecting data.

Each EDM system is designed with an intuitive interface for a streamlined workflow. Operators can reach full proficiency with minimal hands-on training following the installation.

Yes. Our 3D metrology equipment supports standard data formats and connections, allowing seamless integration with many existing platforms. This connectivity enables a real-time feedback loop that improves quality assurance and traceability across your manufacturing procedures.