EDM Intelligent Solutions – 3D Metrology Services Group Serving Myrtle Beach, SC

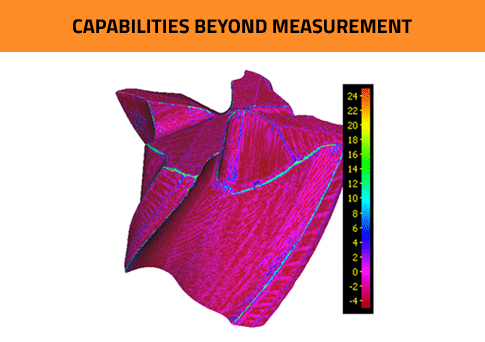

The metrology group at EDM Intelligent Solutions (EDMIS) provides in-depth, non-contact 3D dimensional metrology and dimensional inspection services for parts of almost any shape and size. 3D measurement of form, surface roughness and comparison to nominal CAD models allow us to provide our clients with advanced GD&T inspection services and enhanced 3D roughness parameters for even the most complex components. Our dimensional measurement laboratory and surface roughness testing lab offer both contract and outsource metrology and measurement services.

WHAT IS 3D METROLOGY?

3D Metrology is the scientific study of physical measurements. In the context of manufacturing, it encompasses precision measurement of tools, fixtures and machined components. It is used for measuring length, distance and height (three axes x, y, z), by acquisition of geometric surface points of an object providing infinitely more data than conventional measurement methods. These measurements are often acquired through the use of a coordinate measuring machine (CMM); however new advances in automated optical inspection (AOI) sensor technologies are empowering the evolution of 3D metrology techniques that no longer rely on CMMs.

3D Metrology Company Supporting Industries Across the Globe

3D Metrology Services from EDM Intelligent Solutions are trusted to support OEM customers and manufacturing service providers within the major Aerospace, Automotive, Communications, Defense, Medical and Scientific industries. EDMIS is the source for 3D Metrology Services serving Myrtle Beach, South Carolina including Form Measurement, Difference Measurement, and Surface Roughness Measurement.

APPLICATIONS FOR 3D METROLOGY

Integration of 3D metrology begins in the planning phase of any manufacturing project with the simple question of “How do we measure this feature on this part?”. As a part is designed, this question plays into the manufacturability of the design. In order to make the part, the manufacturing team needs to be able to measure it to ensure that the parts produced meet the original design as planned.

EDM Intelligent Solutions offers assistance in answering the question of how to measure a part. Measurement services to capture dimensions related to form, size and values characterizing the surface roughness of an area of the part are the answer. Using this insight into the parts coming out of a production process allows our customers’ engineering teams to improve their manufacturing processes, reduce waste and increase overall part quality.

High-Resolution Non-Contact Industrial 3D Metrology Services

Our contract inspection and contract measurement services include the following:

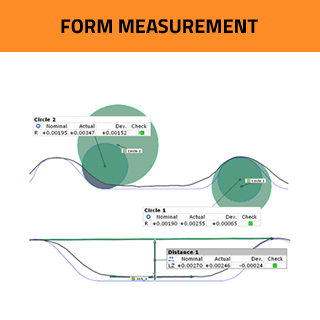

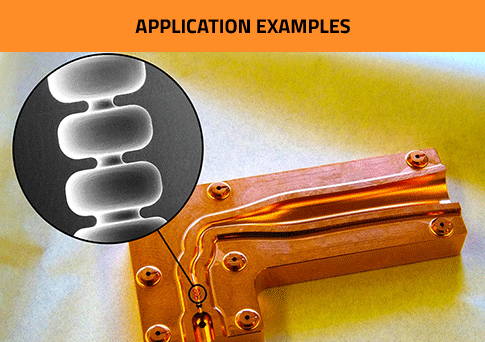

Form Measurement – High resolution 3D scans of piece parts allow for form measurement down to the µm scale. Profiles are cut across the 3D part scan data set and those included points are used to gather various form measurements including radii, angles, slot width, height step, etc.…

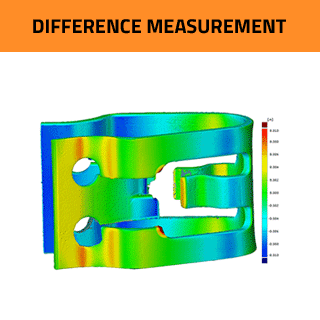

Difference Measurement – 3D scans of the piece part containing millions of data points are compared to ideal CAD models to verify dimensional accuracy of the entire part, or a specific feature.

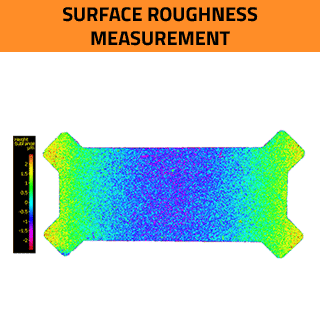

Surface Roughness Measurement – non-contact, high-resolution profile and area-based roughness measurement of surfaces down to 1.2 µinches. Our 3D inspection technology is capable of measuring the surface roughness of almost any material, including metals, ceramics, and plastics.

To learn more about how EDMIS can help you measure your components, contact our metrology team with your request for quote.