EDM Intelligent Solutions – 3D Metrology Services Group Serving Scranton, PA

The metrology group at EDM Intelligent Solutions (EDMIS) provides in-depth, non-contact 3D dimensional metrology and dimensional inspection services for parts of almost any shape and size. 3D measurement of form, surface roughness and comparison to nominal CAD models allow us to provide our clients with advanced GD&T inspection services and enhanced 3D roughness parameters for even the most complex components. Our dimensional measurement laboratory and surface roughness testing lab offer both contract and outsource metrology and measurement services.

3D Metrology Company Supporting Industries Across the Globe

3D Metrology Services from EDM Intelligent Solutions are trusted to support OEM customers and manufacturing service providers within the major Aerospace, Automotive, Communications, Defense, Medical and Scientific industries. EDMIS is the source for 3D Metrology Services serving Scranton, Pennsylvania including Form Measurement, Difference Measurement, and Surface Roughness Measurement.

High-Resolution Non-Contact Industrial 3D Metrology Services

Our contract inspection and contract measurement services include the following:

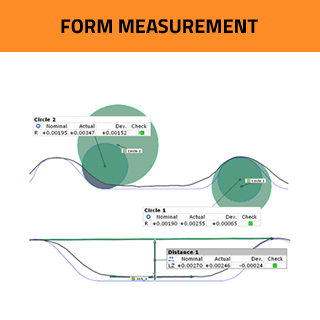

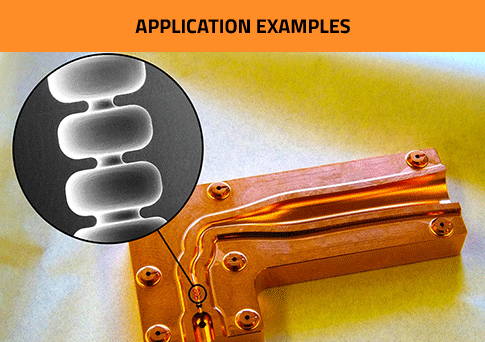

Form Measurement – High resolution 3D scans of piece parts allow for form measurement down to the µm scale. Profiles are cut across the 3D part scan data set and those included points are used to gather various form measurements including radii, angles, slot width, height step, etc.…

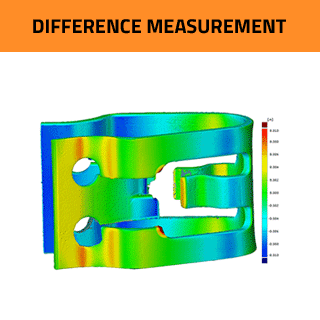

Difference Measurement – 3D scans of the piece part containing millions of data points are compared to ideal CAD models to verify dimensional accuracy of the entire part, or a specific feature.

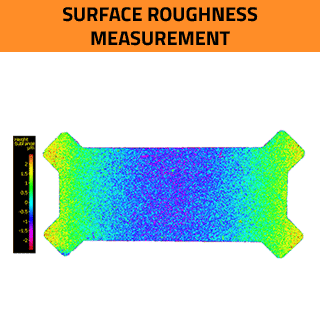

Surface Roughness Measurement – non-contact, high-resolution profile and area-based roughness measurement of surfaces down to 1.2 µinches. Our 3D inspection technology is capable of measuring the surface roughness of almost any material, including metals, ceramics, and plastics.

To learn more about how EDMIS can help you measure your components, contact our metrology team with your request for quote.

EDMIS 3D METROLOGY SYSTEMS AND EXPERTISE

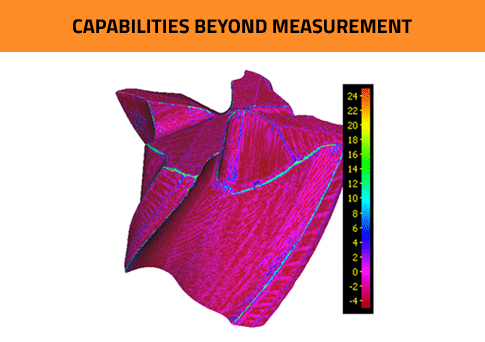

As a multidimensional solutions provider, EDM Intelligent Solutions prides itself on offering unique overall capabilities to our industrial customer base. Having in-house manufacturing, metrology and systems groups allows us to harness the expertise within each of these groups to solve our customers’ most unique manufacturing and measurement challenges.

Every metrology system that is used to measure our customers’ components has been tried, tested and proven to support the tight tolerance high precision machining operations of our manufacturing group within EDM Intelligent Solutions. These systems are trusted so much in fact, that we have an entire systems group at EDMIS that is dedicated to the sales, service and support of the same systems for our customers.

The metrology technicians and applications engineers within both the EDMIS Metrology Services and Systems groups that work with our customers to understand their specific project needs have completed rigorous, in-depth and hands-on training with our CNC machinists and engineers in our manufacturing group operating advanced electrical discharge EDM and CNC machinery to produce real parts, meeting real tolerances that get shipped to real customers. This real-world training gives the metrology team at EDMIS a unique set of fundamentals, technical skills and manufacturing experience from which to draw upon while solving our customers’ measurement challenges. This training regimen and real-world experience are why some of the largest OEMs in the Aerospace, Automotive, Communications, Defense, Medical and Scientific industries have come to rely on EDM Intelligent Solutions as their partner for metrology services and systems.