Wire EDM and Sinker EDM offer performance advantages in production of medical screws, such as cortical, cancellous, lag bone, and transfixation screws that are used to secure implants in the body and accurately position devices used during surgical procedures.

Typically, the screws that remain in the body following a surgical procedure, bone screws, are made from either titanium or cobalt chrome, while screws only used during the surgical process are made from stainless steel. The screw’s driving feature, the internal shape of the screw head (including hex, hexalobular (Torx), squares, and many unique customer-specified shapes) is where EDM machining proves its flexibility and advantage in comparison to traditional manufacturing processes.

Advantages of EDM Machining

Screws produced using EDM manufacturing services are burr-free, chip free, accurate, consistent, structurally sound, and economically producible in short turnaround times. The screws are produced in a wide variety of sizes, shapes, and materials.

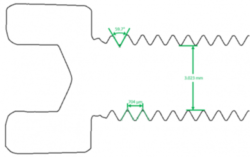

EDM can offer any shaped driving feature such as a three-dimensional side-wall shape with tapers and non-perpendicular side walls. It can also make the base of the screw-driving feature any three-dimensional contour or shape and can even produce a multi-step feature if required.

The precision medical screws that are produced by EDM Intelligent Solutions are inspected for dimensional and surface roughness compliance to the Customer’s design by our in-house metrology experts using advanced 3D Metrology Systems and 3D Metrology Services also offered by EDMIS.

If you have any questions about our precision Medical EDM Machining & Manufacturing services or are interested in learning more about 3D Metrology, contact us today.