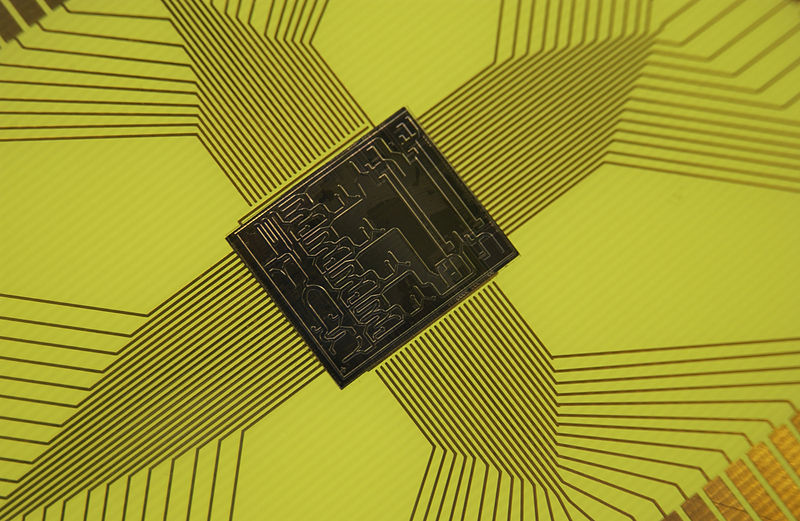

MEMS Production Components, Fixtures and Tooling

Micromachining for MEMS Production

EDM Intelligent Solutions’ precision micro manufacturing processes offer our customers unique microfabrication capabilities for Microelectromechanical Systems (MEMS) applications. With many MEMS components being extremely small, even microscopic, utilizing micro manufacturing techniques that allow aspect ratios of 38:1, features sizes as small as 40um, CNC controlled fine wire EDM machining using microwire diameters as small as 20um, state-of-the-art equipment and experienced engineers, EDM Intelligent Solutions manufactures the most intricate parts with flawless accuracy.

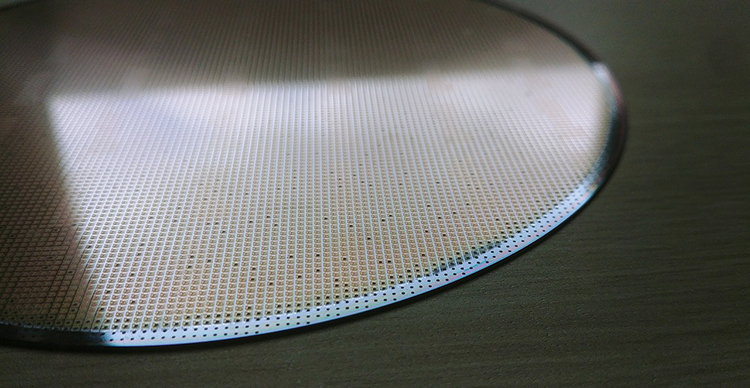

High-Resolution 3D Metrology for MEMS Measurement

Using high-resolution 3D scanning and measurement technologies, we offer in-depth geometric verification of various dimensions of features within MEMS components, automated comparisons of high-resolution 3D part scans against the original nominal 3D CAD model and high-resolution profile and area-based roughness measurement testing of surfaces down to as fine as 1.2 µinches. Our in-house 3D inspection technologies are capable of measuring the surface roughness of almost any material, including metals, ceramics, and plastics.

Ultra-Precision Machine Shop Supporting MEMS OEMs

As a leading precision CNC machine shop in Illinois, companies all throughout the United States choose EDMIS to complete their projects. Typical MEMS projects that take advantage of the micro manufacturing capabilities offered by EDM Intelligent Solutions include prototype and production MEMS components, fixtures and tooling for the production and testing of MEMS assemblies and non-contact 3D metrology of new and existing MEMS components for engineering studies, process improvement and quality assurance controls.