Adaptive Machining Systems

CLM-LSR – LASER-BASED MACHINING SYSTEM

Closed Loop Manufacturing (CLM) systems from EDM Intelligent Solutions pair some of the best high-precision laser ablation machine tools with fully integrated multisensor 3D metrology and tactile inspection technologies, all in one machine. This adaptive manufacturing system brings self-guided production into reality by allowing the machine tool to continuously inspect and adjust its processes in order to meet the ever-shrinking tolerances on high precision workpieces in even the hardest materials. Closed-Loop Manufacturing offers a state-of-the-art, self-optimizing manufacturing intelligence and adaptive machining method for the production of precision components in a variety of overall size ranges.

CLM-LSR System Features & Functionality

- Advanced 3-Axis CNC Machine Tool platform built for efficient 24/7 operation

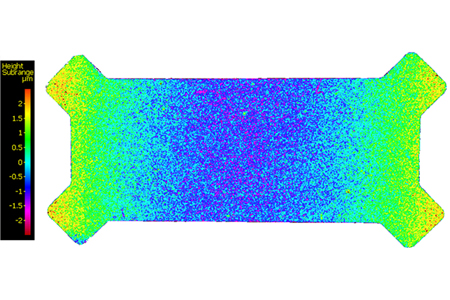

- Automated Form, Roughness and Dimensional Measurement during the machining process

- Real-time Closed Loop feedback of measurement results to the machine control

- Automated measurement based corrections to the machining Program

- Full 3D laser ablation, engraving, surfacing and edge marking

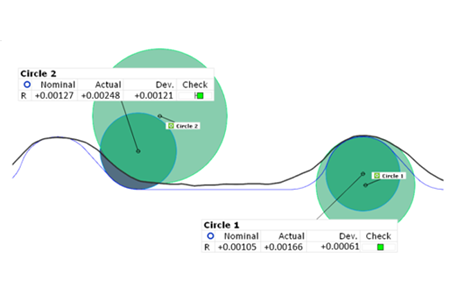

- 3D and 2D True Position Measurement based off of part datums

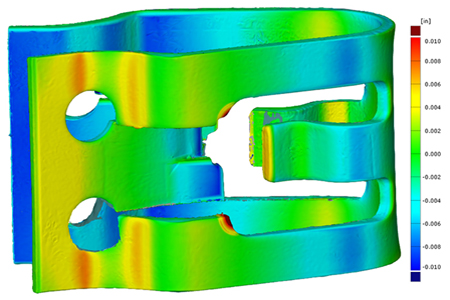

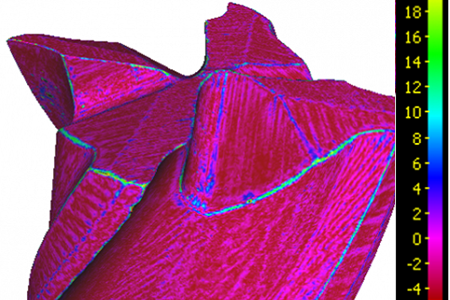

- 3D Difference Measurement vs. CAD model or 3D point cloud

- Automatic part datum alignment procedures to register part coordinate system

- Automatic defect detection and text recognition

- Set up measurements once and run them many times in production environments

- Automatically measure specific dimensions and generate Pass/Fail Reports as PDF

- Offline and Online program generation with automatic program generator

- Intuitive user interface with Administrator, Engineer, and Operator modules

- Integrated barcode scanner to automatically read part information from shop routers

- Ready for automatic machine tending by an EDMIS Robotic Load Unload (RLU) System with FANUC or Mitsubishi Robot

CLM-LSR SYSTEM HARDWARE SPECIFICATIONS |

|

|---|---|

| Control Type | Windows PC |

| X, Y, Table Size | 600 x 700 mm ( 23.6 x 27.5 in ) |

| X, Y, Z Axis Travel | 390 x 390 x 160 mm ( 15.3 x 15.3 x 6.3 in ) |

| Max Payload Weight | 40 kg |

| Workpiece Holding | System 3R, EROWA, 3-Jaw Lever Chuck |

3D IMAGING SENSOR SPECIFICATIONS |

|

|---|---|

| Measurement Speed | ≤ 1.7 million points/sec |

| Objectives | 5x, 10x, 20x |

| Min Measurable Roughness | 0.25 μm, 10 μinch |

| Min Measurable Radius | 3 μm |

| Finest Vertical Resolution | 70 nm |

CLM-EDM – SINKER EDM BASED MACHINING SYSTEM

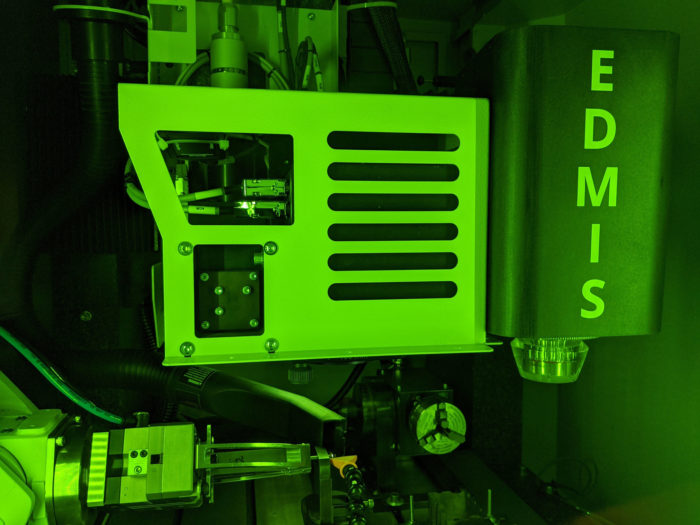

Closed Loop Manufacturing (CLM) systems from EDM Intelligent Solutions pair some of the best high-precision sinker EDM machine tools with fully integrated multisensor 3D metrology and tactile inspection technologies, all in one machine. This adaptive manufacturing system brings self-guided production into reality by allowing the machine tool to continuously inspect and adjust its processes in order to meet the ever-shrinking tolerances on high precision workpieces in even the hardest materials. Closed-Loop Manufacturing offers a state-of-the-art, self-optimizing manufacturing intelligence and adaptive machining method for the production of precision components in a variety of overall size ranges.

CLM-EDM System Features & Functionality

- Advanced 4-Axis CNC Machine Tool platform built for efficient 24/7 operation

- Automated Form, Roughness and Dimensional Measurement during the machining process

- Real-time Closed Loop feedback of measurement results to the machine control

- Automated measurement based corrections to the machining Program

- Full Sinker EDM machining of intricate shapes, blind holes, through holes, and threads

- 3D and 2D True Position Measurement based off of part datums

- 3D Difference Measurement vs. CAD model or 3D point cloud

- Automatic part datum alignment procedures to register part coordinate system

- Automatic defect detection and text recognition

- Set up measurements once and run them many times in production environments

- Automatically measure specific dimensions and generate Pass/Fail Reports as PDF

- Offline and Online program generation with automatic program generator

- Intuitive user interface with Administrator, Engineer, and Operator modules

- Integrated barcode scanner to automatically read part information from shop routers

- Ready for automatic machine tending by an EDMIS Robotic Load Unload (RLU) System with FANUC or Mitsubishi Robot

CLM-EDM SYSTEM HARDWARE SPECIFICATIONS |

|

|---|---|

| Control Type | Windows PC |

| X, Y, Table Size | 550 x 350 mm ( 21.6 x 13.7 in ) |

| X, Y, Z Axis Travel | 350 x 250 x 250 mm ( 13.7 x 9.8 x 9.8 in ) |

| Max Electrode Weight | 75 kgs |

| Workpiece Holding | System 3R, EROWA, 3-Jaw Lever Chuck |

3D IMAGING SENSOR SPECIFICATIONS |

|

|---|---|

| Measurement Speed | ≤ 1.7 million points/sec |

| Objectives | 5x, 10x, 20x |

| Min Measurable Roughness | 0.25 μm, 10 μinch |

| Min Measurable Radius | 3 μm |

| Finest Vertical Resolution | 70 nm |

3D Metrology Measurements Applicable to this EDMIS System

Each Closed Loop Manufacturing System from EDM Intelligent Solutions is capable of completing the types of 3D Metrology measurements shown below.

Competitive 3D Metrology Systems and Solutions

Creating intelligent solutions for manufacturing and measurement challenges is what we do. Over the past 25 years, we’ve completed thousands of measurement and metrology projects. What differentiates EDM Intelligent Solutions 3D Metrology Systems from the competition is our team’s unique understanding of how our systems can be applied to almost every manufacturing process. The EDMIS team of metrology technicians and applications engineers support their colleagues in our tight tolerance CNC machine shop that produces ultra-precision components for customers every day. Harnessing this unique relationship with manufacturing, our metrology team has the experience needed to fully assist our customers integrate EDMIS metrology systems within their manufacturing processes to leverage 3D measurements to improve both their manufacturing processes and products. We are confident that we have a system that can measure your most challenging components and we are ready to work with you to fully understand your metrology needs. To learn more about how EDMIS can help you, contact our metrology systems team with your request for quote.