Machining The Impossible – Sinker EDM Services

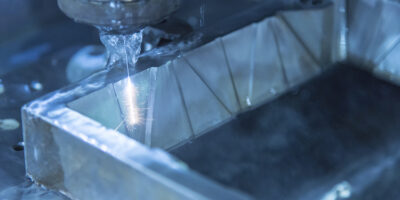

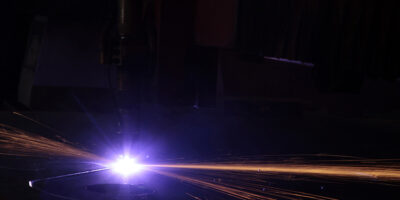

EDM Intelligent Solutions specializes in CNC Sinker EDM (Electrical Discharge Machining), also referred to as Conventional EDM, Die Sinking EDM, Plunge EDM or Ram EDM. Sinker EDM offers the ability to produce complex shapes without inducing stresses into the electrically conductive material and provides low-risk machining solutions for complex components and parts with previous machining already completed. This non-contact machining process is ideal when looking to minimize machining risk and achieve unparalleled accuracy and reliability.

What’s the difference between Sinker EDM & Wire EDM?

Electric current is used to cut or burn away conductive materials in both Wire EDM and Sinker EDM. In both processes, the electrode doesn’t ever touch the material being machined. Unlike Wire EDM, Sinker EDM services do not cut completely through the material (unless desired), resulting in a wider variety of applications, such as blind cavities/keyways, thin walls, or cross-sections. This versatility makes sinker EDM an efficient technology for components of stamping dies and injection molds. Our vast library of EDM generator technologies offers the best surface finishes available in a multitude of materials. By maintaining strong and ongoing relationships with our technology partners we are able to stay on the forefront of Sinker EDM capabilities and meet the ever-evolving needs of our customers. EDM Intelligent Solutions provides prototyping, production, and contract manufacturing Sinker EDM services. We will work with you in providing the best solution to your most difficult EDM project requirements.