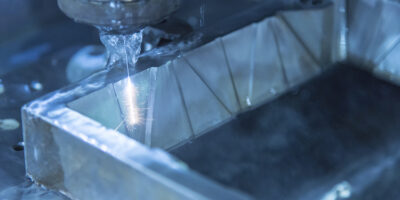

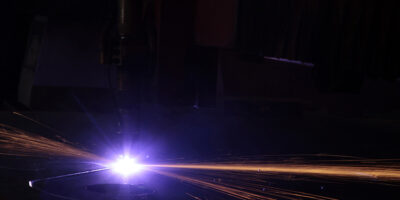

Sinker EDM Materials

EDMIS is dedicated to fulfilling your specific requirements. By leveraging strategic sourcing partnerships with a diverse network of qualified material suppliers nationwide, we can manufacture your components from the precise materials you need. This facilitates timely delivery and eliminates any potential roadblocks related to material availability.

All vendors and material suppliers to EDM Intelligent Solutions meet strict quality standards to ensure that the components we produce meet the highest standards commonly required by the aerospace, automotive, communications, defense, medical and scientific industries.

Regarding materials, Sinker EDM is compatible with numerous metals unsuitable for conventional machining, like milling and turning. The Sinker EDM erosion process effectively machines hardened materials like tungsten carbide. Sinker EDM electrodes gently shape softer materials such as copper, while extremely thin materials are protected from damage and precisely machined since the electrode does not touch the workpiece.

Materials Compatible with Sinker EDM

EDM Intelligent Solutions has completed thousands of Sinker EDM projects using diverse materials, such as those listed below:

- Aluminum

- Brass

- Copper

- Exotic Metals

- Molybdenum

- Titanium

- Tungsten

- Carbide

- Tool Steels

- A-2, A-5, A-6, A-8

- D-2, D-3, D-5

- DC-53

- H-11, H-12, H-13, H-19

- L-6

- M-1, M-2, M-3, M-4, M-42

- O-1, O-6

- S-1, S-7

- T-1

Please contact us if your specific material does not appear on the list. We will help determine if it can be machined using our CNC Electrical Discharge Machining and assist you in sourcing the material.