What is Micro Manufacturing?

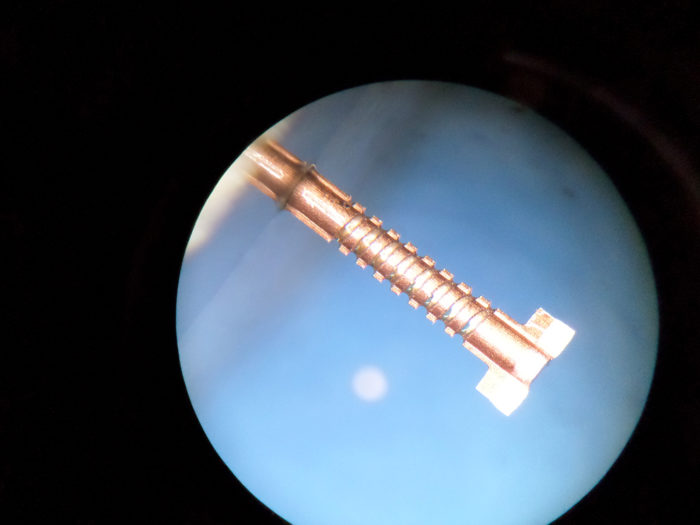

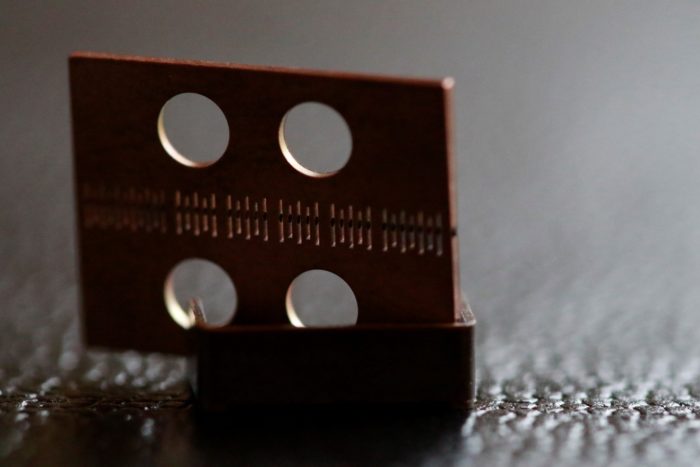

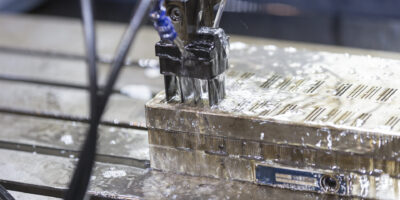

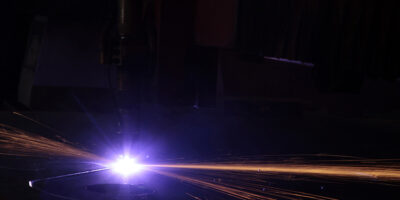

Manufacturing at a micro scale requires machining processes capable of micron level tolerances and repeatability. Many micromachined components incorporate features that are only a few microns in size and require absolute accuracy. Sometimes referred to as micro/meso-scale mechanical manufacturing (or M4 processes), micromachining typically creates products using specialized machinery that is purpose built to establish superior accuracy and consistency between the miniature parts being produced. Ongoing product miniaturization in a multitude of industries is requiring ever smaller and tighter tolerance components to be produced.

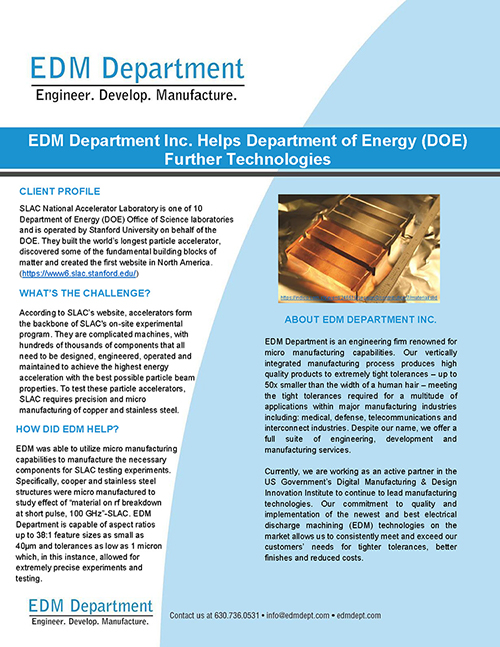

EDM Intelligent Solutions has been at the forefront of unique micromanufacturing techniques applied to traditional electrical discharge machining processes for 25 years. Coupled with extremely high resolution automated 3D metrology systems, the micro manufacturing team at EDMIS is able to machine some of the tiniest, most intricate and extremely delicate parts that can be designed.

If your part is too small for the other CNC machine shops that offer micromanufacturing, odds are that it is perfect for the EDM Department at EDMIS.