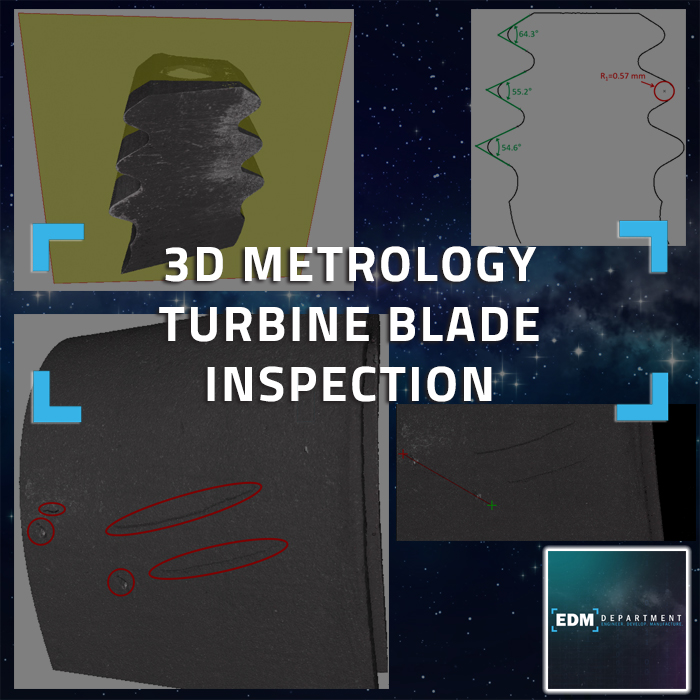

3D Metrology Turbine Blade Inspection

February 11, 2020

Demand for increasingly complex turbine blades, including airfoil, root geometries, and shaped cooling holes with tighter tolerances and accuracies, has risen due to improved engine performance levels and efficiencies required in the new generation of aero-engines and land-based gas turbine engines. Our 3D Metrology services use advanced 3D scanning and measurement technologies to inspect both straight and shaped cooling holes, leading-edge surface roughness, blade root geometry, airfoil characteristics and for detection of surface defects to improve blade performance.

Our 3D Metrology services provide in-depth, non-contact 3D measurement and inspection of almost any shape, size, form and surface roughness to a diverse set of industries including aerospace, automotive and mold tool and die. Our 3D Metrology Services group is comprised of experts in the fields of tight tolerance manufacturing, inspection, 3D optical and laser metrology and flexible automation and manufacturing solutions.

Interested in learning more? Visit our Turbine Blade Inspection page to learn more, or contact us today.