3D Metrology Systems Rosemont, IL

EDM Intelligent Solutions – 3D Metrology Systems Group Serving Rosemont, IL

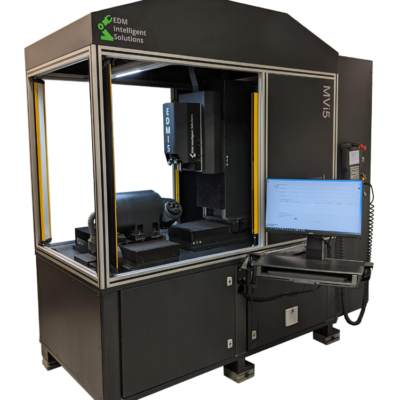

The systems group at EDM Intelligent Solutions (EDMIS) offers automated optical inspection, dimensional metrology, dimensional inspection, and surface roughness measurement solutions including industrial 3D metrology centers and robotic metrology systems for in-line and near-line production measurement applications. Our CNC based inspection machinery provide innovative solutions for engineering process development and automated quality monitoring of manufacturing and production processes.

WHAT IS 3D METROLOGY?

3D Metrology is the scientific study of physical measurements. In the context of manufacturing, it encompasses precision measurement of tools, fixtures and machined components. It is used for measuring length, distance and height (three axes x, y, z), by acquisition of geometric surface points of an object providing infinitely more data than conventional measurement methods. These measurements are often acquired through the use of a coordinate measuring machine (CMM); however new advances in optical sensor technologies are empowering the evolution of 3D metrology techniques that no longer rely on CMMs.

3D Metrology Company Supporting Industries Worldwide

Automated 3D Metrology Systems from EDM Intelligent Solutions are at work 24/7 supporting OEM customers and manufacturing service providers within the major Aerospace, Automotive, Communications, Defense, Medical and Scientific industries. EDMIS is the source for 3D Metrology Systems that companies in Rosemont, Illinois rely on for 3D Metrology Centers, Robotic Metrology Systems, Automated Metrology Systems, Near Line Metrology Systems, Closed Loop Manufacturing, and Machine Tending Systems.

DIMENSIONAL METROLOGY AND SURFACE ROUGHNESS MEASUREMENT

Each metrology system from EDMIS provides in-depth, non-contact 3D measurement and inspection of components with almost any shape, size, form and surface roughness. The dimensional metrology and surface finish test reports that are created by the EDMIS metrology systems are used to improve engineering processes and control the quality of full-scale manufacturing and production.

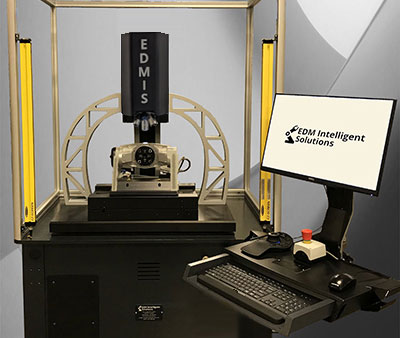

SIMPLE AND SECURE USER INTERFACE

Featuring an easy to use system control software graphical user interface (GUI) known as EDMISi, each 3D metrology system is ready to support Operators, Engineers and Managers that require a simple and trusted measurement solution. The integrated online programming environment within the EDMISi makes quick work of measurement routine creation. Built-in collision avoidance functionality verifies that each measurement program is free of potential collisions between the workpiece and metrology system. Dimensional measurements and surface roughness testing results are automatically completed and output to the user via the Feature Extraction module within the EDMISi interface. Simple pass/fail reports are available along with in-depth engineering study reports used for process improvement.

STANDARD SYSTEMS AND CUSTOMIZABLE METROLOGY PLATFORMS

Our full range of standard metrology platforms can be customized to meet the specific measurements that our customers’ applications require while allowing for easy integration of the systems within the customers’ existing production environments. Whether this be machine tool manufacturing intelligence software, machine tending robot arms, custom work holding fixture tooling, integration with existing CAD/CAM packages, additional safety equipment like hard doors and fencing, EDMIS works with each customer to make their technology adoption process seamless.

If you have any questions about our Intelligent Solutions for 3D metrology and manufacturing or are interested in learning more, contact us now!

EDM INTELLIGENT SOLUTIONS – FANUC AUTHORIZED SYSTEMS INTEGRATOR

We are proud to be an official FANUC Authorized Systems Integrator incorporating industry proven FANUC Robotics and FANUC CNC products within our unique 3D Metrology solutions. This partnership with FANUC America Corporation empowers the team at EDM Intelligent Solutions with the factory level training, extensive automation know-how and enhanced technical experience to effectively integrate FANUC Robotics, CNC and motion control systems.

NAICS Code 334519 Classified

3D Metrology Systems from EDM Intelligent Solutions

Competitive 3D Metrology Systems and Solutions

Creating intelligent solutions for manufacturing and measurement challenges is what we do. Over the past 25 years, we’ve completed thousands of measurement and metrology projects. What differentiates EDM Intelligent Solutions 3D Metrology Systems from the competition is our team’s unique understanding of how our systems can be applied to almost every manufacturing process. The EDMIS team of metrology technicians and applications engineers support their colleagues in our tight tolerance CNC machine shop that produces ultra-precision components for customers every day. Harnessing this unique relationship with manufacturing, our metrology team has the experience needed to fully assist our customers integrate EDMIS metrology systems within their manufacturing processes to leverage 3D measurements to improve both their manufacturing processes and products. We are confident that we have a system that can measure your most challenging components and we are ready to work with you to fully understand your metrology needs. To learn more about how EDMIS can help you, contact our metrology systems team with your request for quote.