Electronics Ultra Precision Molded Part Measurement Using High-Resolution 3D Scanning

Executive Summary

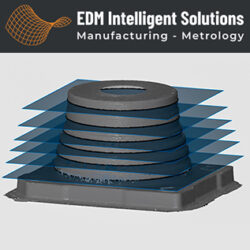

High-performance electronic devices often rely on ultra precision molded components that must meet tight dimensional tolerances. EDM Intelligent Solutions provides advanced, non-contact 3D metrology services capable of analyzing complex part geometries with micron-scale accuracy. This white paper highlights the measurement of a precision-molded plastic component using our MVi5 3D Metrology Center, focusing on form measurement, height step, and angular form analysis.

Overview of 3D Metrology Capabilities

Our metrology systems generate high-resolution 3D mesh models of complex parts, from which we extract 2D profiles and cross-sections for detailed dimensional analysis. These measurements include radii, slot width, step heights, circularity, angles, and more—making them ideal for quality control of precision-molded plastic components.

Key capabilities include:

- Micron-level non-contact 3D scanning and mesh creation

- Profile slicing to measure form features such as diameter and slot width

- Step height and angular form measurements for dimensional verification

- Fully digital inspection process with traceable output

Application Case Study: Precision Molded Part Inspection

Component Overview

- Type: Ultra Precision Molded Part

- Material: Injection Molded Plastic

- Metrology System: MVi5 3D Metrology Center

- Metrology Services: Form Measurement, Height Step, Angular Form

Inspection Process

The inspection began with a non-contact 3D scan of the molded plastic part using the MVi5 3D Metrology Center. The high-resolution scan data was converted into a 3D mesh model, capturing the entire surface topology of the component.

Using the mesh model, EDMIS engineers created 2D profile slices through specific part regions to evaluate key dimensional features. Measurements included radii, slot width, step heights, and angles—each compared against design tolerances to ensure product conformity.

Results & Value Delivered

- Accurate 3D form analysis of ultra precision molded plastic parts

- Identification of dimensional deviations via profile-based inspection

- Fully traceable digital measurements suitable for quality reporting

- Non-destructive, high-speed inspection of complex molded geometries

Conclusion

Precision molded plastic parts used in electronics require exact dimensional control to ensure assembly compatibility and device reliability. EDM Intelligent Solutions’ 3D metrology systems provide non-contact inspection solutions that support process validation, defect detection, and continuous quality improvement for high-volume plastic components.

About EDM Intelligent Solutions

EDM Intelligent Solutions delivers precision metrology and machining services for the electronics, medical, aerospace, and defense sectors. Our MVi5 3D Metrology Center offers automated, high-resolution inspection capabilities to help manufacturers meet tight tolerances and improve product quality.

Downloadable PDF of Applications Report

Let’s Discuss Your Application

Have a challenging measurement problem? Our engineers are ready to help.