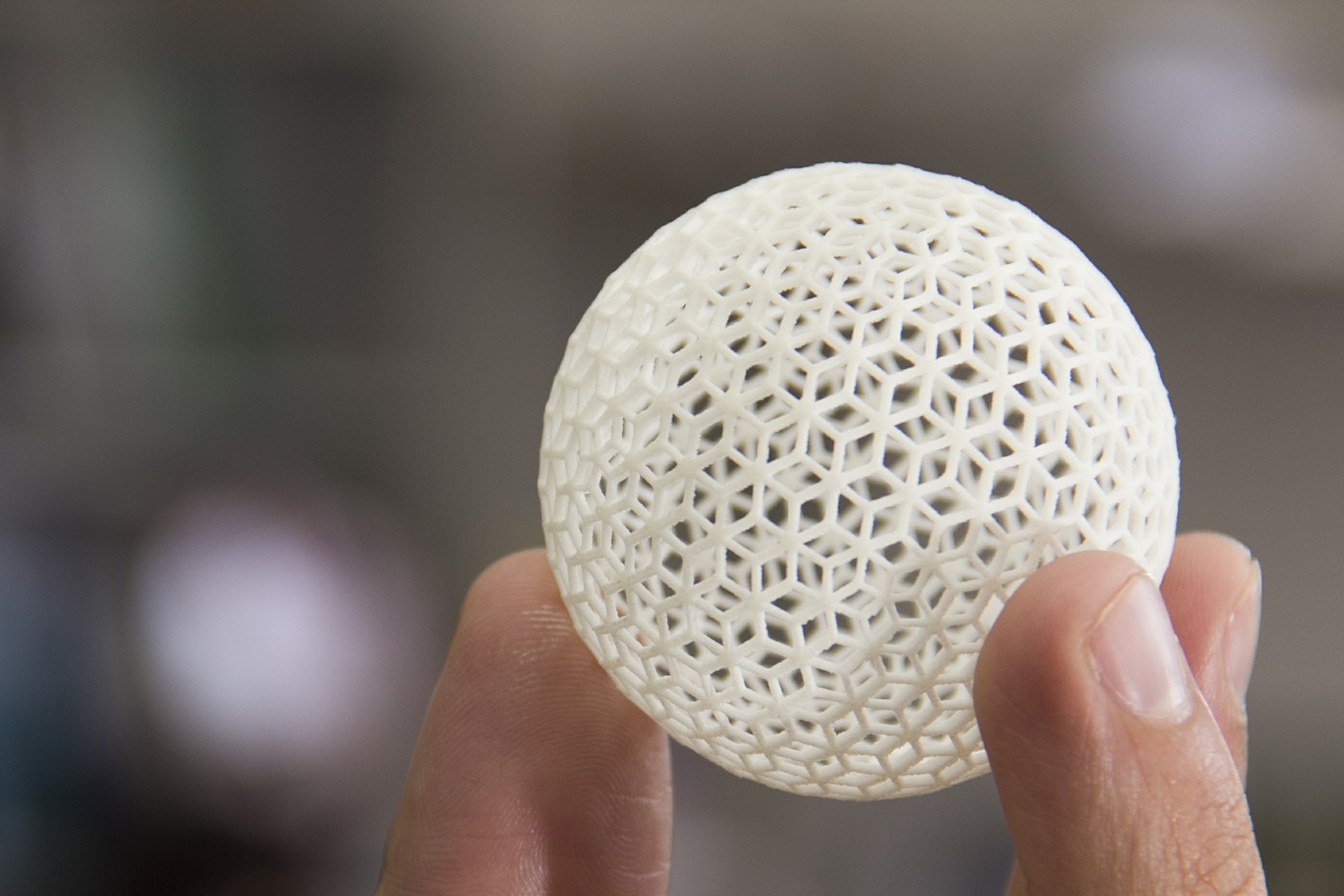

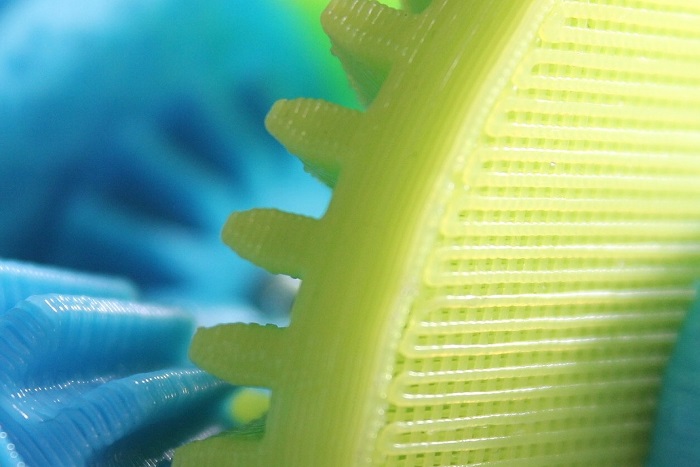

As the spread of 3D printing and other additive manufacturing processes grows, the need for tailored measurement and inspection systems is rising. Our automated and robotic metrology systems are well suited for inspection of almost any shape that can be printed or grown. That coupled with the ability to measure the printed part’s surface roughness and finish characteristics allows the end-user to gain an in-depth understanding of their additive manufacturing process that can be applied to improve overall printed part quality and process yield.

We’re proud to offer our 3D Metrology Systems for inspection and measurement of 3D printed components that require the highest level of inspection detail. Each system offers an ease of use that allows everyone on your production floor to operate it safely and efficiently. 3D inspection using form measurement, difference measurement and surface roughness measurement is available on each of the systems that we offer. Our streamlined human-machine interface allows your operators, managers, and engineers access to quick and repeatable measurements. This creates a package that allows the inspection task to be brought straight out to the production floor, creating more efficiency for your overall operations.