Machining the Impossible – Fine Hole EDM Drilling Services

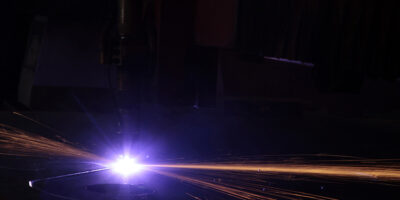

EDM Intelligent Solutions offer unique, fine hole EDM drilling services of blind and through holes in a wide variety of electrically conductive materials. Our purpose-built CNC operated EDM small hole drilling machines can produce fine diameter holes as small as 30 microns (0.0012”) in some of the toughest conductive materials available like carbide and nickel. High precision micro hole sizes, excellent hole edge quality, superior surface finish, improved overall part accuracy and excellent hole consistency is achieved through the use of cutting edge EDM generator technologies within the micro hole drilling machines and specialized electrode materials that allow the extremely fine diameter electrodes used to stand up to the EDM drilling spark erosion process. These advanced materials also reduce the electrode wear encountered during the spark machining process. The lower the wear of the electrode, the more holes each electrode can machine before it needs to be replaced.

What is EDM Hole Drilling?

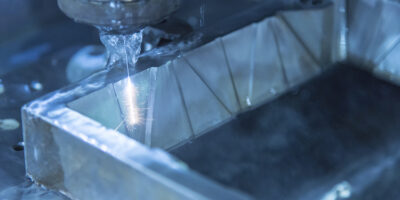

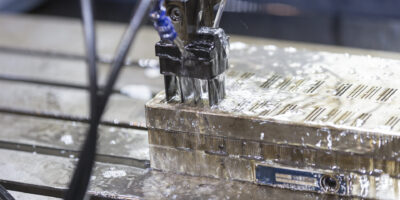

Similar to Sinker EDM, micro hole drilling with electrical discharge machining uses electric current, carried to the workpiece through a pipe shaped or solid electrode, to erode or burn away electrically conductive materials. The electrode doesn’t ever touch the material being machined so deflection of the pipe electrode is minimized when compared to drilling holes with a traditional cutting tool. During EDM Hole Drilling the tube electrode is energized by the advanced EDM generator and spun at high speeds while high pressure flushing fluid is pumped through the tube electrode to flush out the workpiece material that is being cut away by the electrical erosion. This process allows EDM Intelligent Solutions to produce micro diameter, accurate holes quickly in nearly all types of conductive metals. Our EDM Drilling machines are designed for the highest levels of accuracy with incredible reliability. Each micro hole drilling machine also has uniquely integrated automation of the machining process that results in increased productivity, making EDM Small Hole Drilling the perfect choice for projects with small diameter hole quantities ranging from just a few all the way up to high volume production applications requiring thousands of holes in hundreds or thousands of pieces.