MACHINING THE IMPOSSIBLE – FINE WIRE EDM SERVICES

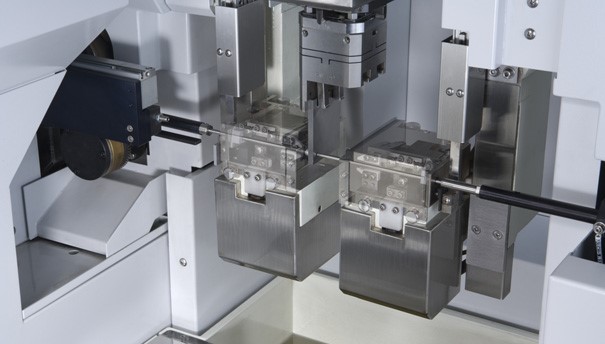

Micro CNC Wire cutting EDM services are what we do best. We offer ultra-precision tolerances, as tight as 1µm, for an array of industries and micromanufacturing applications. Our fine wire cut electrical discharge machinery have the capacity to run multiple wire sizes, including microwire as small as 20µm (0.0008″) in diameter. Our experience and state-of-the-art equipment enable us to provide accurate, repeatable, and quality parts and components made from any type of conductive material.

WHAT IS WIRE EDM?

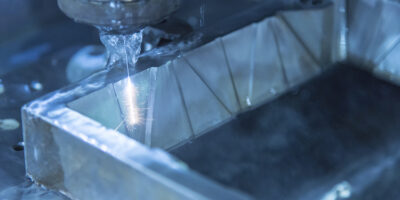

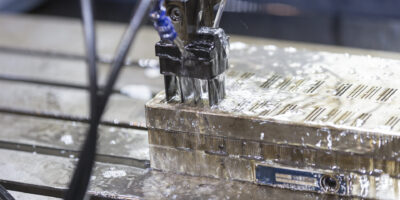

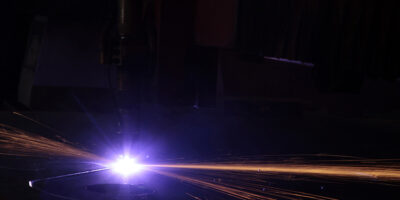

The Wire EDM (Electrical Discharge Machining) process uses a thin single strand of wire, which is fed through the workpiece in conjunction with deionized water. The wire is spooled between two guide rollers, much like the blade on a band saw, that are guided in a path controlled by the CNC. During this process, electric current is used to cut away the conductive materials of the workpiece and leave behind a smooth surface that requires no additional finishing or polishing processes. This process is typically used when low residual stresses are desired as there is little change in the mechanical properties of the material. During this process, the cutting wire doesn’t ever touch the material. Instead, the cutting takes place when sparks form between the material and the cutting wire. Deionized water is used because it deionizes the spark gap, flushes away the particles removed from the workpiece, and acts as a cooling medium. Wire EDM machining is widely used within a multitude of industries for creating components by cutting intricate shapes in numerous conductive and oftentimes delicate materials.