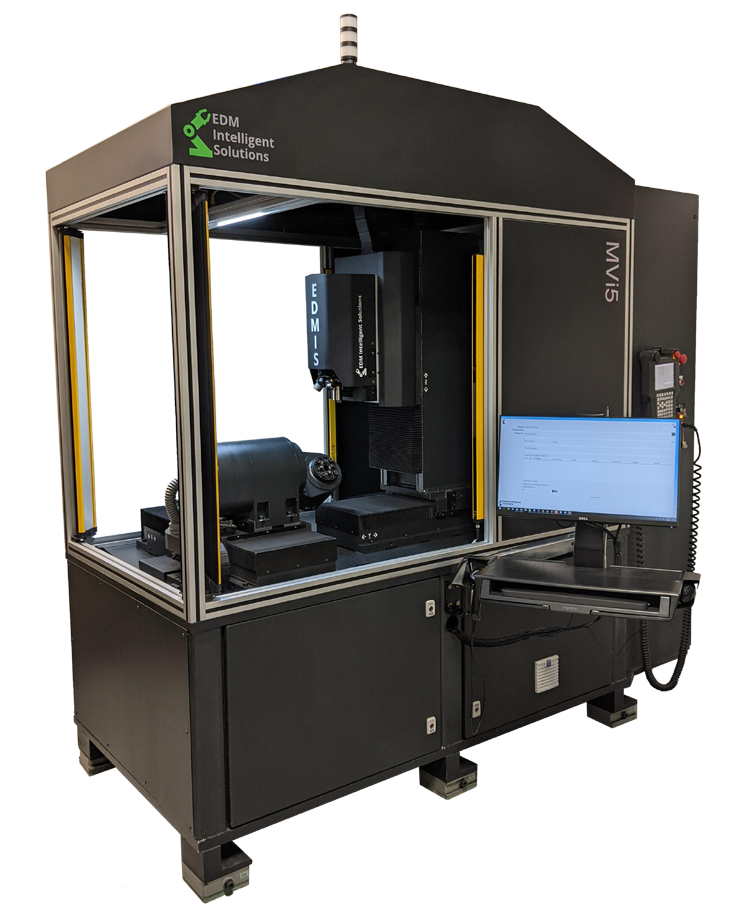

MVi5 3D METROLOGY CENTER

The MVi5 automated 3D metrology center from EDM Intelligent Solutions is geared towards applications that require the highest level of measurement and inspection detail while still maintaining an ease of use that allows all users on the production floor to operate it safely and efficiently. The streamlined human-machine interface (HMI) as well as total access control functionality allows operators, managers, engineers and administration managed access to quick, repeatable and traceable measurement all in a robust machine tool based package that allows precise measurement and inspection tasks to be brought out directly to the production floor. Easily scalable, the MVi5 comes ready to integrate with production floor automation like machine tending robots and the industrial internet of things (IIOT) so that it can support the fast-paced and flexible manufacturing environments of the future.