Ultra Precision CNC Machine Shop Serving Industries Worldwide

For 25 years, EDMIS has been dedicated to providing world class precision machining services for OEM and research and development customers within the major Aerospace, Automotive, Communications, Defense, Medical and Scientific industries across the United States and the world.

Jet engine turbine components and mechanical flight surface actuators for the Aerospace industry. Injection molds and fuel injectors for the Automotive industry. Interconnect assemblies and tooling for the Communications industry. ITAR registered machining services for the Defense industry. Implants and surgical tools for the Medical industry. Waveguides, beam channels and sensor components for the Scientific industry. These are just a small sample of all the types of components that EDM Intelligent Solutions has manufactured. There really aren’t many types of parts that EDMIS has not worked on in some form over the last 25 years serving these industries. No project is too big or part too complex or tolerance too tight for EDM Intelligent Solutions which makes us the preferred partner for OEM manufacturers nationwide. To learn more about how EDMIS can help you contact our manufacturing team with your request for quote.

Custom Machined Parts for R&D and Contract Manufacturing

We specialize in manufacturing custom parts per print and provide contract manufacturing of full production quantities, along with small batch prototypes, utilizing the manufacturing services and expertise required to offer our customers consistent, high-quality precision components at globally competitive costs and lead times. Our vertically integrated manufacturing process produces high-quality products with tolerances from 1 to 100 microns, sometimes almost 50 times smaller than the width of s human hair, allowing us to meet the tight tolerances required for a multitude of applications.

EDM Intelligent Solutions – Manufacturing Services Group Serving Scottsbluff, NE

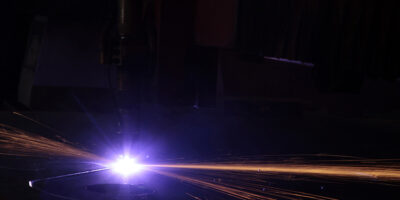

The manufacturing group at EDM Intelligent Solutions (EDMIS) is renowned for precision electrical discharge machining (EDM). Utilizing industry leading CNC controlled EDM machinery and technologies, we produce high-quality products with fine details and tolerances as tight as 1 micron. Our expertise in enhanced machining parameters creates components with advanced surface finishes and extremely tight positional accuracies. EDMIS is the source for all EDM Manufacturing Services serving Scottsbluff, Nebraska including Wire EDM, Sinker EDM, EDM Hole Drilling and Laser Ablation.

Machining the Impossible

Our CNC machine shop offers electrical discharge machining capabilities not found in many other shops. The EDM Department at EDMIS is made up of highly skilled CNC machinists and engineering professionals that have the decades of experience and expertise required to produce components with close tolerances as tight as 1 micron accuracy. When typical CNC machine shops are not able to make it, the manufacturing team at EDM Intelligent Solutions can. Contact us today to discuss your part design and how we can apply an intelligent solution to make your impossible part possible.

Electrical Discharge Machining Services

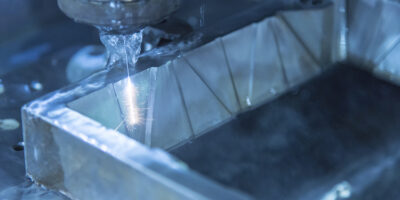

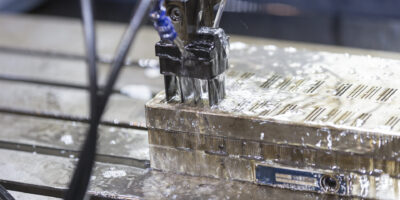

Commonly known as spark eroding, die sinking, wire erosion and wire burning, EDM is an advanced fabrication process that utilizes controlled electrical discharges to remove or erode conductive material from a blank workpiece. This process relies on a tool, called the electrode, that is either a solid shape of conductive material or a thin wire. The electrode is moved in relation to the workpiece in a motion that results in machining of the final intended shape. As the electrode gets ever closer and closer to the surface of the workpiece, and electrical arc is formed which causes the erosion of the blank material. A unique feature of the EDM manufacturing process is that the tool never actually contacts the workpiece. The electrical arc “jumps” from the tool to the workpiece in a series of rapidly pulsating discharges. This non-contact machining allows for extremely tight tolerances to be achieved.

Services Provided by EDM Intelligent Solutions, Tolerances Listed in Microns

⦁ Wire EDM (corner radii as small as 25 micron, accuracies as tight as 1 micron)

⦁ Sinker/Plunge/Ram EDM (features as small as 40 micron)

⦁ EDM Hole Drilling (holes as small as 40 micron in diameter)

⦁ Precision Grinding (tolerances as tight as 2 micron)

Micromachining Capabilities

As industries continue to miniaturize their products due to demand for ever smaller and more efficient technologies, the need for tighter tolerance machining and manufacturing processed continues to grow. It is not uncommon to see various components be manufactured at EDM Intelligent Solutions that are not visible to the naked eye. The extremely high magnification automated 3D measurement and inspection systems produced by our 3D Metrology Systems group are directly integrated into the micro manufacturing operations and processes used by the EDM Department at EDMIS to machine impossibly small and delicate parts while meeting tolerances as tight as 1 micron.

Micro Manufacturing Services Provided

⦁ Fine Wire EDM (wire diameters as small as 20 microns)

⦁ Micro Sinker EDM (aspect ratios up to 38:1, surface finishes to 4Ra micro inch)

⦁ Micro-Milling (cutter sizes as small as 25 micron)

⦁ Laser Ablation (laser beam size as small as 50 micron)

⦁ 3D Metrology (non-contact measurement and inspection with nano-meter resolutions)

OUR FACILITY, A PRECISE ENVIRONMENT FOR PRECISION MACHINERY

EDM Intelligent Solutions understands that strict control of the CNC machining environment is key in being able to manufacture the highest quality components for our customers. Advanced thermal control systems with compartmentalized machining bays allows and integrated temperature monitoring equipment keeps the high precision electrical discharge machinery producing tight tolerance parts 24/7. An in-depth foreign object debris and damage (FOD) program coupled with enhanced dust filtration and part handling techniques ensure that the parts that are machined at EDMIS are preserved with no imperfections. These important environmental controls and programs allow EDM Intelligent Solutions to provide manufacturing services to customers in the Aerospace, Medical and Scientific industries that have rigorous standards in terms of part cleanliness and preservation like the UHV Handling required for components machined for Department of Energy Research Laboratories and Institutions.

AS9100D AND ISO 9001:2015 CERTIFIED, ITAR REGISTERED MANUFACTURING SERVICES

The success of our customers is always one of the largest drivers for the success of EDM Intelligent Solutions. As an AS9100D and ISO 9001:2015 certified CNC Machine Shop our adherence to strict industry quality standards is ensured. Our dedicated team of machining and engineering professionals strive for only the highest levels of precision aided by the best CNC electrical discharge machinery available integrated within a highly organized, temperature-controlled facility that supports ultra-precision manufacturing. When your most intricate parts require the tightest tolerances and best surface finishes available, you can rely on the EDM Department at EDM Intelligent Solutions to machine the impossible.